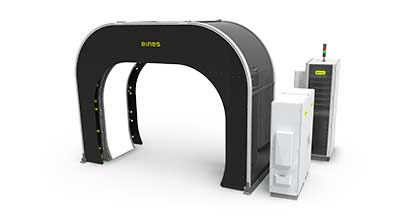

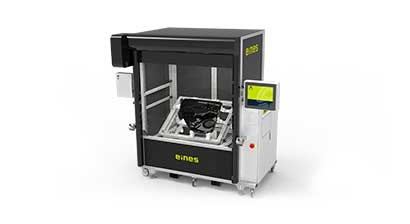

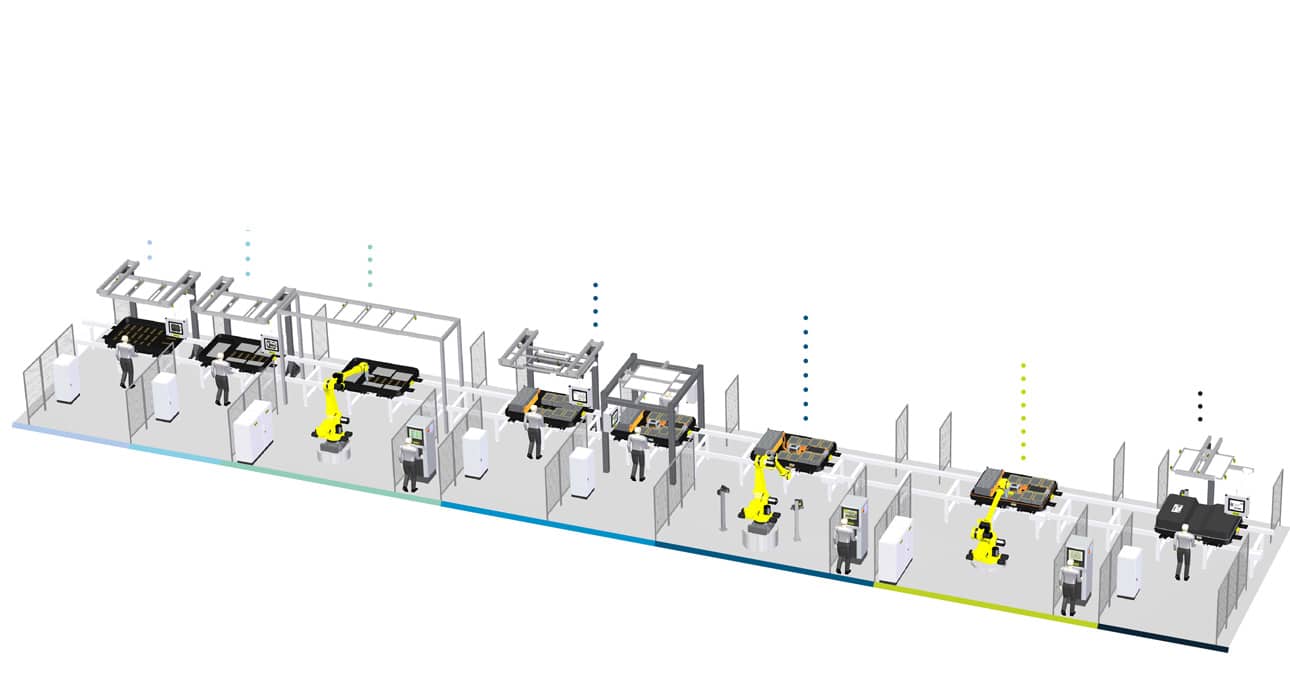

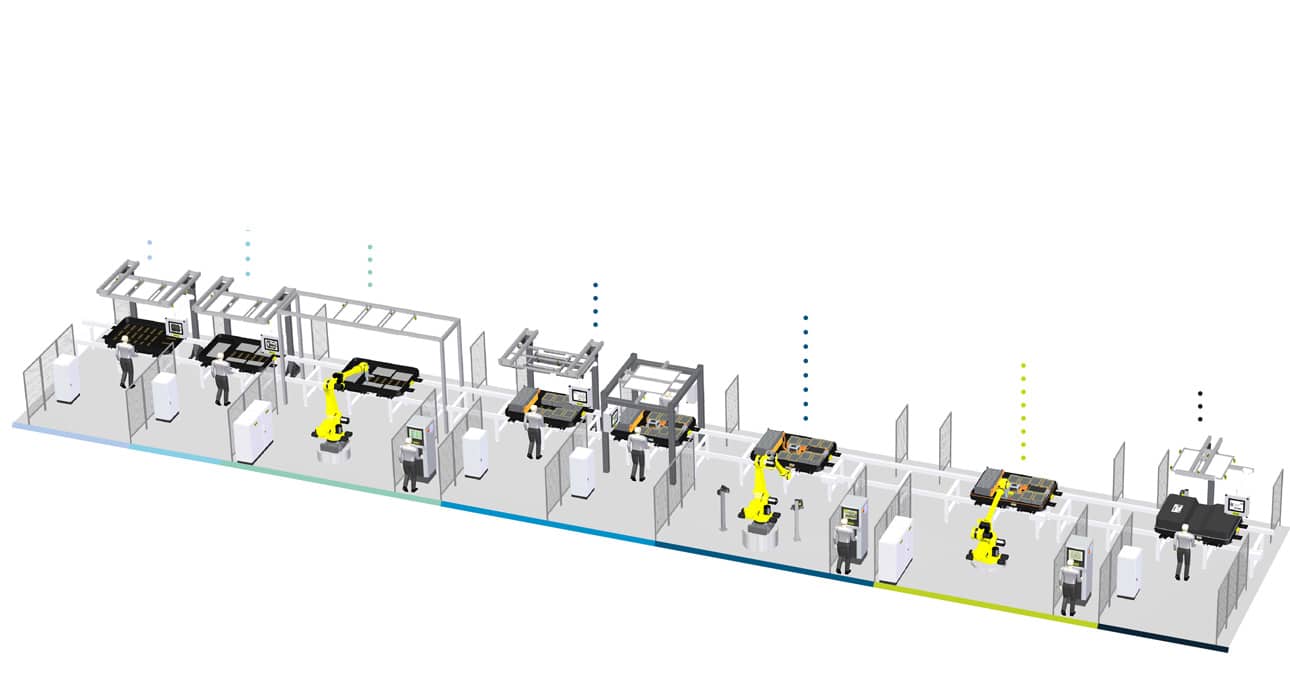

Battery Assembly Full Control

Eines EV Battery Suite has multiple applications for quality control in the entire battery assembly process.

Thanks to the concept’s flexibility, the solution can be adapted to the customer line to reach the highest performance.

- Cold Plate Inspection

- TIM and Component Check

- 3D Robot Guidance

- Cover seal’s position, continuity and dimension

- Optical Character Recognition (OCR)

Multiple Applications in Battery Assembly Line

We can adapt our several applications depending on the disposition of your line. Our high knowledge and experience in automotive allows us to adapt our Battery Quality Control solution to your plant’s needs.

Functions

Thermal Interface Material Inspection

Component Inspection

3D Robot Guidance

Battery Cover Seal Control

Decoding & OCR

Analysis and Reporting

Multiple reports available for each station can be obtained and customised.

Big Data includes results, pictures and measurements, providing the value to analyse trends by shifts, lines, stations, etc. Therefore, improvements can be made in the system by applying predictive and preventive actions.

The monitoring is real-time, so operators can manage the results without stopping production.

Remote Assistance 24 Hours

We will adapt to your needs at any place in the world thanks to our assistance team.

Our Customer Success Service is focused on promoting a proactive work culture in partnership with our customers. The purpose is to help you as a customer and end user to get more value out of your purchase and stay in close contact with us to share feedback about the installation.