For Spec Check and Error Proofing

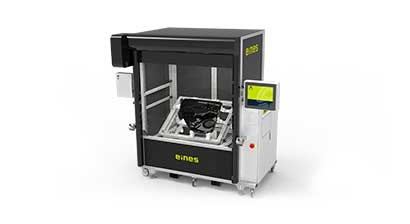

Component Check Tunnel

AI-Powered Component Check System

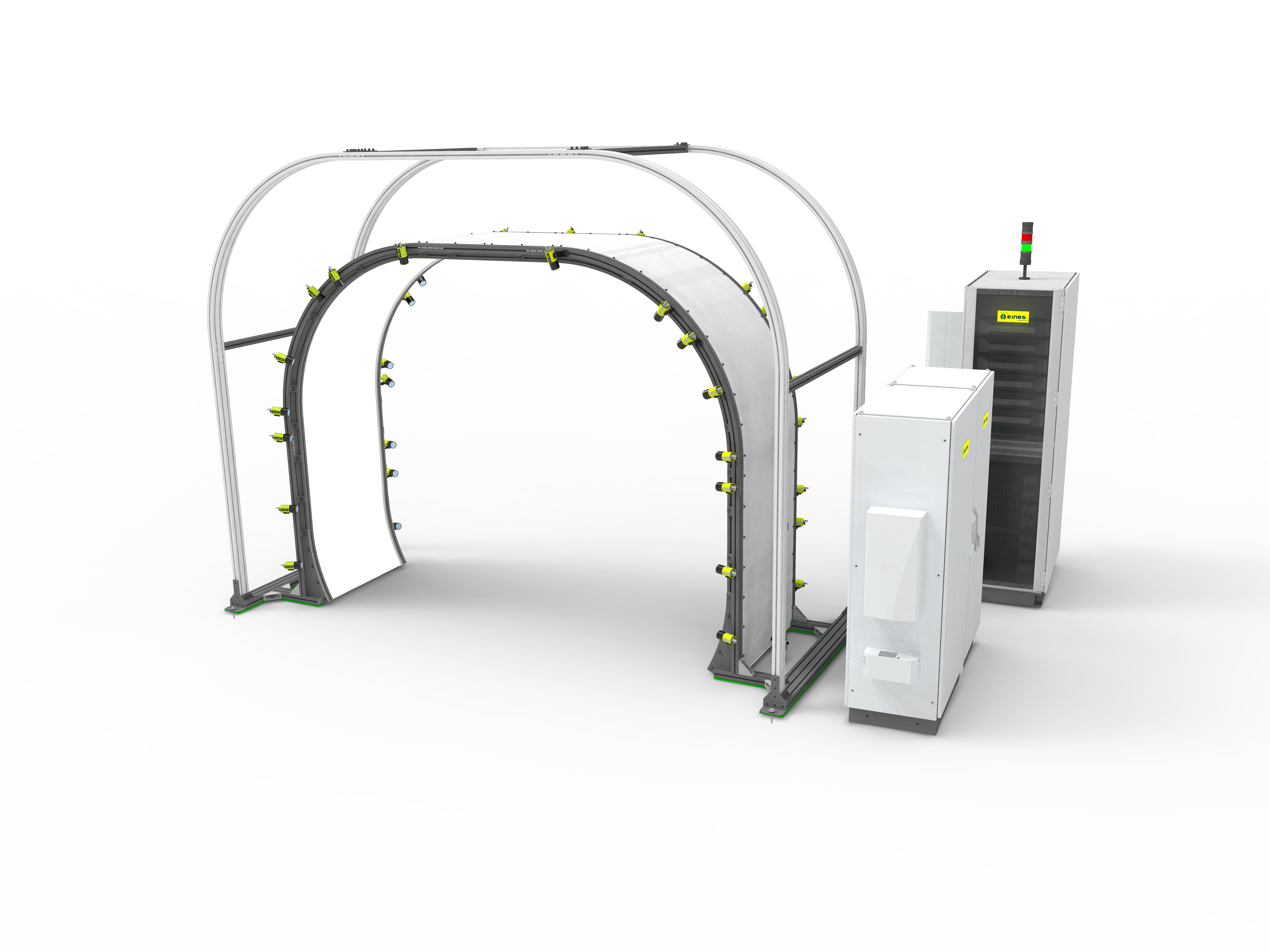

Component Check Tunnel performs multi-error proofing capabilities to control different components.

This way, customers can guarantee the correct part-to-spec correspondence, such as vehicle badges for type and versions, wheel safety nuts or hub types, chrome or rubber finishings, moulding colors, plate foam, traceability or legal labels, etc.

How AI-Powered Component Check System works?

Functions

Mouldings

Part Location

Alerts and Warranties

Optical Character Recognition

Badges

Data Matrix

Traceability and Executable Actions

100% Inline

Inline Tunnel for Parts

The flexibility of the system allows it to adapt to any type of line. The Multi Error Proofing Tunnel-based system has a small footprint and parts move trough in Automated Guided Vehicles (AGV) or other means of transport.

You can also add to the Component System:

Metrology Inspector + Damage Detection

Less hardware, more capabilities, more cheaper

Gap and Flush Inspector between assembled automotive closures nad bodies is critical in modelling vehicle’s aerodynamic performance. Our vision system tunnel is a simple and non-touch 3D measurement solution. It has a small footprint and needs no extra security measures.

In Body in White and Final Assembly can be performed with an extra zebra light arch that, thanks to Artificial Intelligence Algorythm, is able to learn different types of defects.

Remote Assistance 24 Hours

We will adapt to your needs at any place in the world thanks to our assistance team.

Our Customer Success Service is focused on promoting a proactive work culture in partnership with our customers. The purpose is to help you as a customer and end user to get more value out of your purchase and stay in close contact with us to share feedback about the installation.