For headliners, doors, instrument panels and more

Interiors and Parts Inspection

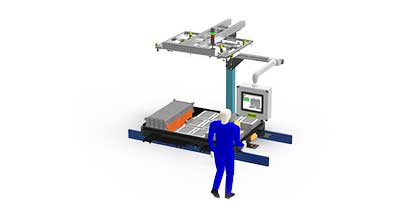

Headliners Inspection

Headliners Check System is a workbench capable of performing a visual inspection.

It can check several different models without changing tools.

First, the operator is guided in assembly operations, then, the part is visually inspected, and the defects are immediately shown and stored for traceability.

- Flexible and Customizable

- Cost Effective and Low Maintenance

- Reporting and Big Data

Doors Inspection

The system analyses each door and vehicle part in a personalised way according to the customer.

It is an integrator of various component checking: electronic devices, lighting or decorative inserts, colour recognition, presence or absence of parts, relative measurements and so on.

- Front Door Panel

- Rear Door Panel

- Deep Learning for Component Check

Instrument Panels Inspection

EINES® Instrument panel check system checks several points, such as the presence or absence of parts, colour recognition or relative measurements in all kinds of instrument panels.

- Flexible and Customizable

- Big Data to track and find root causes

- Simple and Sustainable

Light Panels Inspection

EINES Light Panel Inspector checks the absence and presence of parts, position and color. Thanks to Artificial Intelligence, it can adapt to any model and fit your specifications.

- AI Algorithm

- Big Data to track and find root causes

- Simple and Sustainable

Component Check Tunnel Inspection

Component Check Tunnel performs multi-error proofing capabilities to control different components.

This way, customers can guarantee the correct part-to-spec correspondence, such as vehicle badges for type and versions, wheel safety nuts or hub types, chrome or rubber finishings, moulding colors, plate foam, traceability or legal labels, etc.

- Part Location

- Big Data to track and find root causes

- Artificial Intelligence