Vision System to Optimize Performance

Automated pose estimation allows to create tools designed to measure and track human movement.

Therefore, optimization of a work station which measures ergonomics and provides assembly assistance, the operator’s efficiency can enormously increase.

- Critical Quality Control

- Safety

- Security

- Problem Detection & Root Cause Analysis

- High first-run Capability Rates

- Service Life Cycle

- Error Prediction

- Assembly Steps Aid, Control and Check

Features

Pick & Place

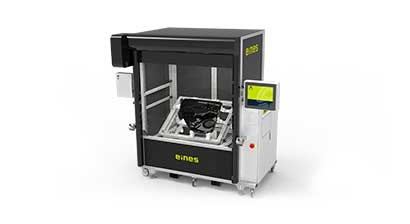

Ergonomics Optimization

Safety

Analysis and Reporting

Big data includes results, pictures and measurements, providing the value to analyse trends by shifts, lines, stations, etc. Therefore, improvements can be made to the system by applying predictive and preventive actions.

Operators can manage the results in real-time, without stopping production.

Manufacturing Assistance

It allows monitoring of the assembly process through the scene and part detection, as well as tracking the operator’s hands or body. Also, it interacts with the operators through visible and acoustic signals and feedback from them through interpreting their gestures. This way, the solution has been designed to automate the process.

Human Optimization Ergonomics

The system ensures the proper performance of specific actions, such as lifting weights or using manipulators, to avoid injuries, safety risks, scrap parts and manufacturing defects.

Efficiency can be achieved by optimising the worker and workplace relationship: it reduces incidents and increases work performance.

Safety

It allows monitoring a production plant or warehouse for safety with forklifts at zebra crossings and areas with poor visibility. When proximity to a dangerous object is detected, the operator is warned and actions are taken automatically. Also, it stops a machine if it detects a hand nearby and tracks 3D robots location to improve interaction.

In addition, the system can also identify if the operator is wearing the required safety equipment.

Remote Assistance 24 Hours

We will adapt to your needs at any place in the world thanks to our assistance team.

Our Customer Success Service is focused on promoting a proactive work culture in partnership with our customers. The purpose is to help you as a customer and end user to get more value out of your purchase and stay in close contact with us to share feedback about the installation.