In the era of Industry 4.0, vision systems are transforming automotive manufacturing by enabling automation, ensuring quality, and optimizing processes. Vision systems integrate high-resolution cameras, sensors, and AI-based software to analyze visual data. Unlike standard cameras, they extract actionable insights by identifying patterns, detecting flaws, measuring tolerances, and predicting failures. This precision is critical in the automotive industry, where strict quality standards and tight tolerances define success.

Applications of Vision Systems in Automotive Manufacturing

1. Quality Inspection

Vision systems automate quality checks across the production line, from specific components to fully assembled vehicles.

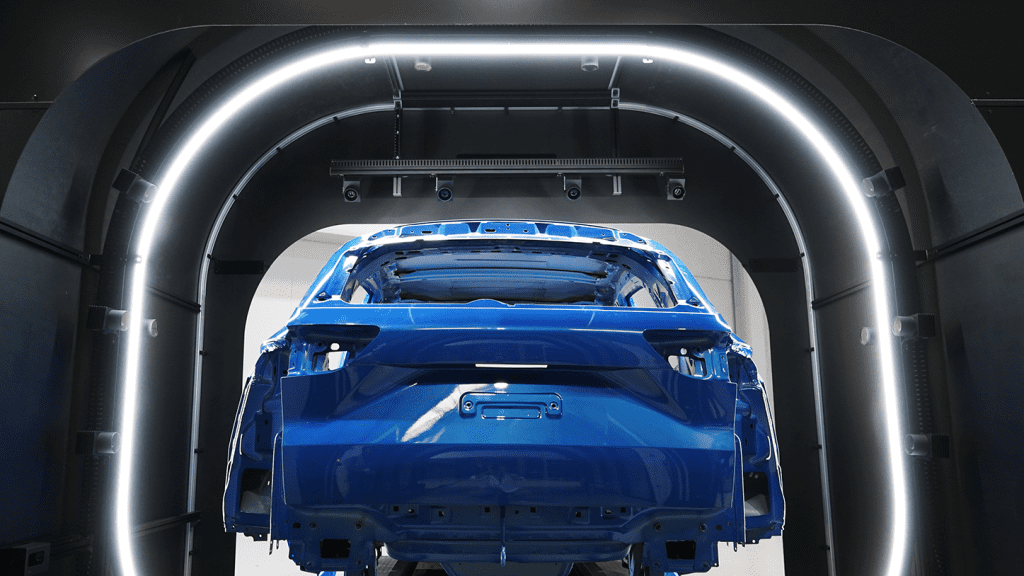

- Paint Shop Inspections: Eines Paint Inspector Tunnel (ESFI) identifies standard paint defects like orange peel, dust, and crater, as well as pinholes and dents, with superior sensitivity. This system also classifies the importance of manual or automatic repair and the defect type. These inspections are vital in ensuring flawless paint application.

- Final Assembly Checks: Eines Scratch and Dent Tunnel (ESDI) detects imperfections, such as scratches and dents caused during the assembly process, providing a last line of defence before vehicles leave the factory and are delivered to the end customer.

- Component Inspection: Once assembled, the Component Check Tunnel meticulously examines specific parts, including car emblems, side mirrors, mouldings, wheels, and any components specified by the customer, to ensure they meet the required standards (part-to-spec).

Both paint shop and assembly inspections benefit from the real-time data generated by vision systems. This traceability allows manufacturers to analyze and optimize processes, enhancing efficiency and productivity.

2. Dimensional Measurement

Misaligned parts can lead to wind noise, water leaks, aerodynamics, and aesthetic problems. This is why precision measurement is paramount in automotive manufacturing, and vision systems enable detailed dimensional measurements using machine vision.

Eines Metrology Tunnel (EIFIS), thanks to stereo vision technology, can measure flush and gap tolerances at hundreds of points on the car body, without stopping production, ensuring proper fit and finish.

If your production is low and you prefer to maintain manual processes, these measurements can be performed with Eines Handheld Metrology Device (EH2) using laser profile technology.

These measurements are essential for vehicle sealing and soundproofing, directly affecting customer satisfaction.

3. Inspection of Interior and Exterior Parts

Quality assurance extends to individual parts like doors, cockpits, headliners, and instrument panels. Vision systems can detect flaws, verify wiring connections, the presence and absence of components and even ensure proper welds and much more is a muti-error proofing systems that can check any customer’s needs.

With integrated QR code readers, these systems also streamline part identification, enabling seamless tracking and serialization.

Manufacturers, including Tier 1 suppliers, rely on these systems to uphold high-quality standards in every component, ensuring superior vehicle performance and safety.

4. Wheel and Tire

Eines provides advanced solutions for Wheel and Tire Quality Control, including:

- Sequence Identification: Ensures tires match rims using Flow Control and ERIS systems to prevent mismatches.

- Sticker Verification: Uses the ESIS system to check compliance with regional label regulations.

- Valve Insertion Inspection: Ensures correct valve placement, either manually or robotically.

- AutoDot System: Reads DOT codes on tires for enhanced traceability and control.

- ERSI System: Detects surface defects on rims, enabling data analysis for predictive maintenance and quality control.

5. Robot Guidance

Last but not least, Vision systems also can assist robots in accurately performing tasks like robot 3D positioning. By transmitting positional data, these systems enable robots to make real-time adjustments, ensuring precise operations throughout the production process.

Are there challenges in implementing Vision Systems?

Despite their advantages, vision systems are not without challenges. Integrating them into existing production lines can be complex and requires expertise. The initial investment can be substantial, especially for their High-Quality Hardware and Software.

However, with continuous advancements in AI and sensor technology, these barriers are gradually diminishing. Today we can say with no doubt that vision systems are becoming more affordable, intuitive, and capable of self-calibration, which is paving the way for broader adoption.

If you want to have more information about these new solutions, you can contact us.