Metrology Checking in Body Shop and Assembly

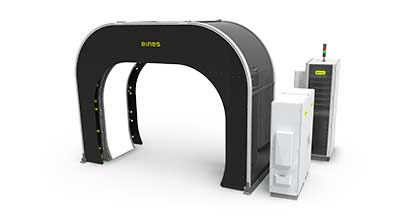

Gap & Flush Tunnel

Dimensional Measurement in any Section

Gap and Flush inspection between assembled automotive closures and bodies is critical in modelling a vehicle’s aerodynamic performance.

Our vision system tunnel is a simple and non-touch 3D measurement solution. It has a small footprint and needs no extra security measures.

Furthermore, it is flexible to the customer’s needs, as any vehicle variant can be configurated anytime and adapts to the required cycle time.

- More than 100 measurements

- Can measure in different materials

- Simple and Sustainable

Functions

Gap and Flush Measurement

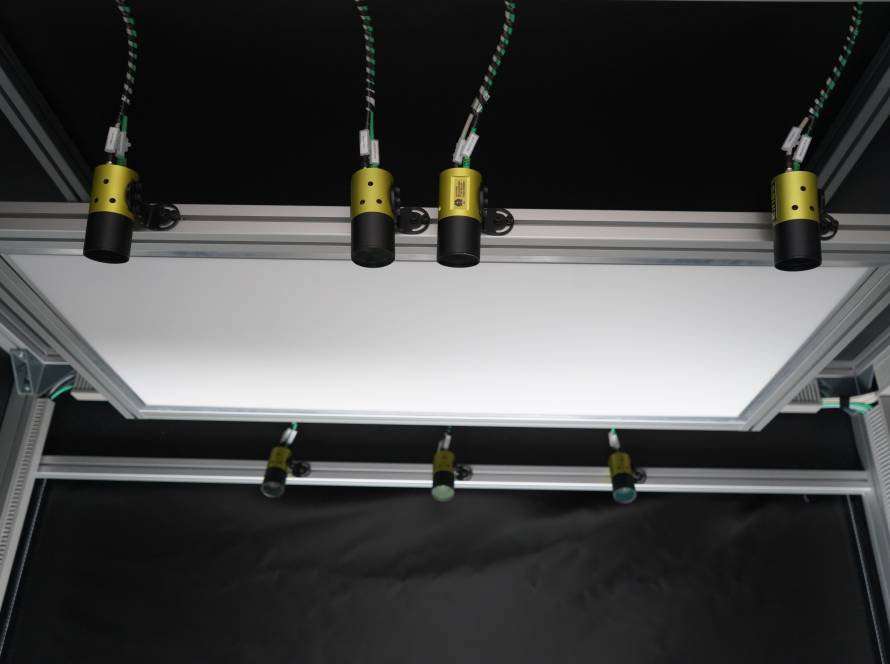

Stereo Vision

Specular Highlight

Symmetry Analysis

100% Inline Measurement

Data Analysis and Storage

Traceability and Executable Actions

Reporting and Big Data

Big Data in Automotive

The vision system provides immediate feedback in a user-friendly interface of different devices such as computers, mobile phones, smart watches and more. It also has integrated reporting by collecting the data, which is key to analysing the performance.

Component Check and Damage Detection

- Component check can be performed with the same cameras to control vehicle badges, wheel type and security nuts, chrome / rubber finishings, moulding colours, plate foam, traceability/legal labels, etc.

- Damage Inspection in Body in White and Final Assembly can be performed with an extra zebra light arch that, thanks to Artificial Intelligence Algorythm, is able to learn different types of defects.

Remote Assistance 24 Hours

We will adapt to your needs at any place in the world thanks to our assistance team.

Our Customer Success Service is focused on promoting a proactive work culture in partnership with our customers. The purpose is to help you as a customer and end user to get more value out of your purchase and stay in close contact with us to share feedback about the installation.