DOT and ROM Code Reader is essential in tire manufacturing to ensure safety, compliance, and operational efficiency. Read why precise DOT and ROM code reading is indispensable and the risks associated with neglecting this process.

Importance of DOT and ROM Code Reading

- Identification of Manufacturing Date: The last four digits of the DOT code specify the tire’s manufacturing date. Tires generally last 6 to 10 years, depending on usage and storage. For example, a DOT code ending in “2023” indicates manufacture in the 20th week of 2023. Proper tracking helps ensure tires are replaced before they become unsafe.

- Traceability and Quality Control: Accurate DOT code tracking aids inventory management, defect tracing, and efficient recalls. This is crucial for maintaining product safety and quality.

- Prevention of Incorrect Mixes: Correct DOT reading prevents mixing tires of different ages or specifications, which can adversely affect vehicle handling and safety.

Consequences of Improper DOT Reading

- Safety Risks

- Production Issues

- Maintenance Challenges

- Legal and Liability Issues

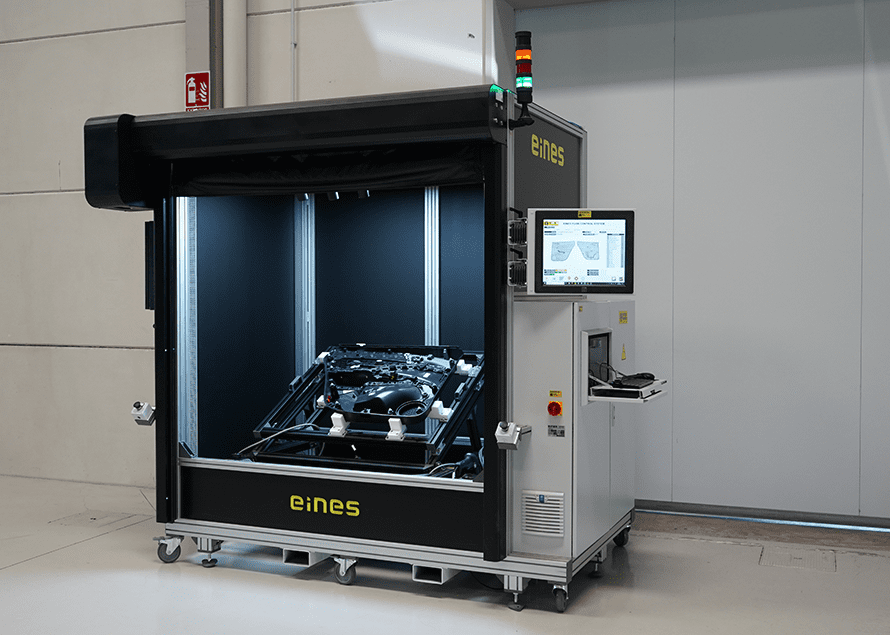

Introducing the AUTO DOT READER (ADR) by EINES VISION SYSTEMS

To tackle these critical issues, EINES VISION SYSTEMS introduces the AUTO DOT READER (ADR), an advanced automated solution for tire inspection. Leveraging advance artificial vision, LED lighting, sensors, and deep learning algorithms, the ADR seamlessly integrates into production lines to deliver precise, autonomous reading of DOT and ROM codes. This state-of-the-art system modernizes tire quality control by ensuring 100% accurate inspections, eliminating manual errors, and boosting operational efficiency.

| Problem Solved | Differentiation | Key Benefits |

| Human Errors: eliminates manual reading mistakes | Precision: Accurate DOT and ROM code reading | Complete Automation |

| Operational Efficiency: speeds up inspection, reducing review time. | Advanced Technology: deep learning and OCR for unmatched precision | Time Savings |

| Operational Costs: Cuts reliance on specialized personnel and safety measures | Experience and Reability: backed by over 30 years of expertise and Konica Minolta’s support | Cost Reduction |

| Integration and Adaptability: Easily fits into existing production lines with no major modifications | Quality Improvement | |

| Zero Maintenance: operates autonomously post-installation with no additional upkeep. |

WEBINAR TIME!

Join Us in Smart Systems Live Demo: The Future of Wheel & Tire Quality Control

On September 19th, experience the future of tire inspection with our live demo. Discover how the AUTO DOT READER can transform your tire manufacturing processes.

Event Details:

- Asia: 8:30 AM CET | Tokyo: 9:30 PM | Shanghai: 8:30 PM | Hosted by Javier Gil and Konica Minolta

- German: 10:00 AM CET | Hosted by Juan Carlos García

- Spanish: 4:30 PM CET | 8:30 AM Mexico Time | Hosted by Salin Alvarez

- English: 6:00 PM CET | 12:00 PM Detroit Time (USA) | Hosted by Mike Koper

What you will learn?

- Live demo

- Advanced inspection techniques

- State-of-the-art software

- Integrated technologies

- Seamless integration

- Expert insights