Why Steering Wheel Alignment Measurement Is Critical Before Wheel Alignment

In automotive manufacturing, precise steering wheel alignment is crucial before aligning the wheels to ensure a smooth driving experience. A misaligned steering wheel can lead to handling issues, reduced safety, and increased wear on tires and brakes. At EINES, we’ve developed an advanced system that automates the measurement of steering wheel alignment using cutting-edge vision technology.

What Is Steering Wheel Alignment and Why Is It Important?

Steering wheel alignment ensures that the vehicle’s wheels are properly aligned with the steering direction. If misaligned, the vehicle might drift or pull to one side, leading to compromised control and safety. Poor alignment can also cause uneven tire wear, making your vehicle less fuel-efficient and increasing the risk of accidents.

Measuring the steering wheel alignment before wheel alignment guarantees that the steering is perfectly synced with the wheels, preventing handling issues down the line.

Do you know you can Automate this Measurement with Vision Technology?

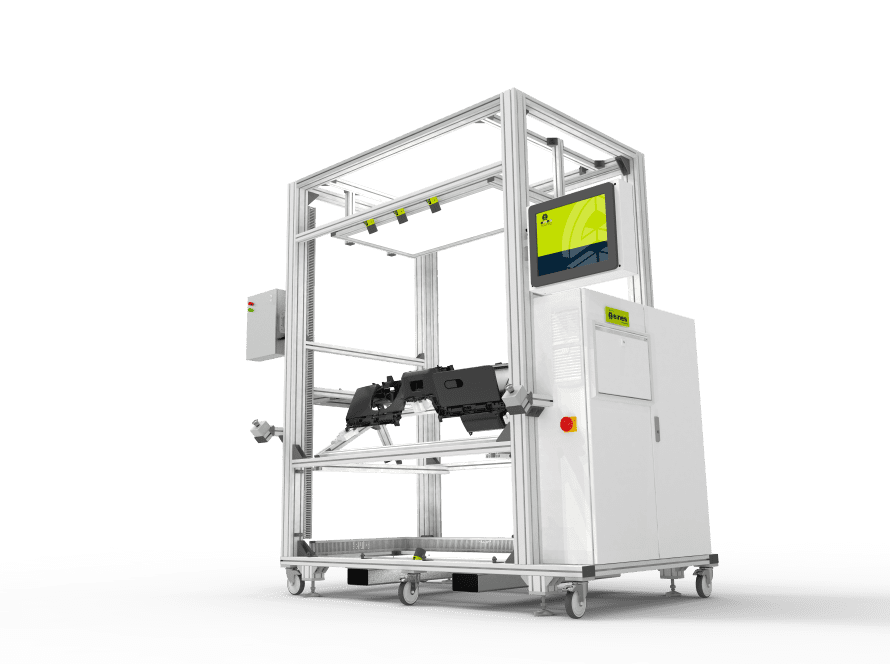

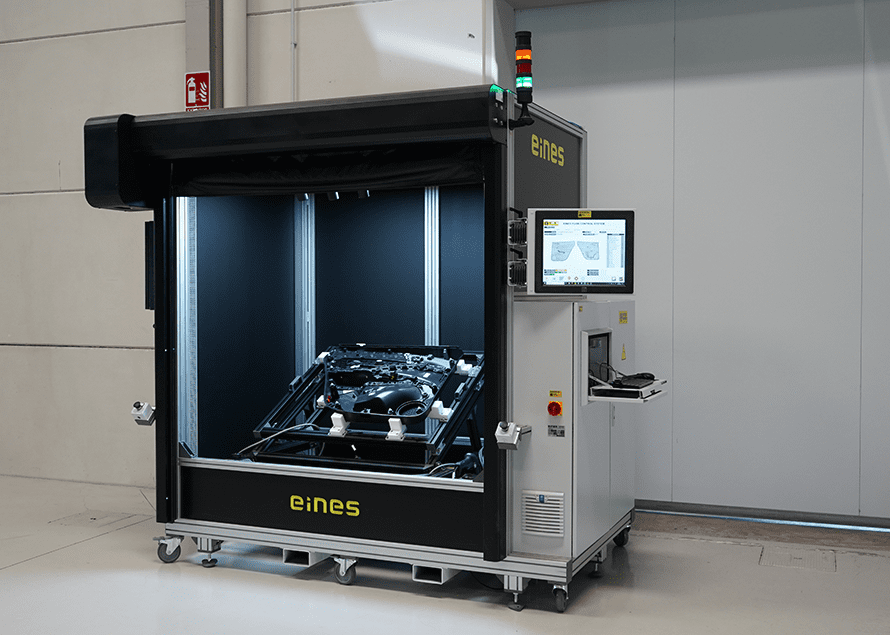

At EINES , thanks to high-resolution cameras and artificial vision technology we can install a system capable of automating the alignment process. This system can be installed within inspection tunnels like the All-in-One or Tunnel EIFIS where it simultaneously conducts other quality checks like flush and gap measurements, surface inspections, and external component assessments.

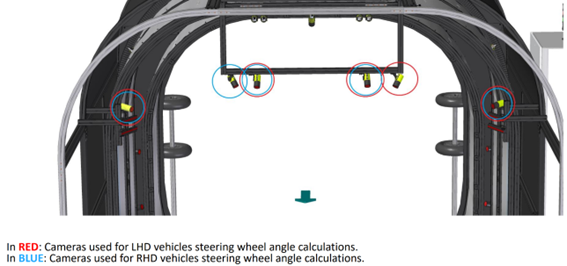

For example, In the picture below we can see an EIFIS tunnel to which cameras have been added exclusively for this measurement. Some cameras would be in charge of checking car models with the steering wheel on the left side and other models with the steering wheel on the right side.

How Does the System Work?

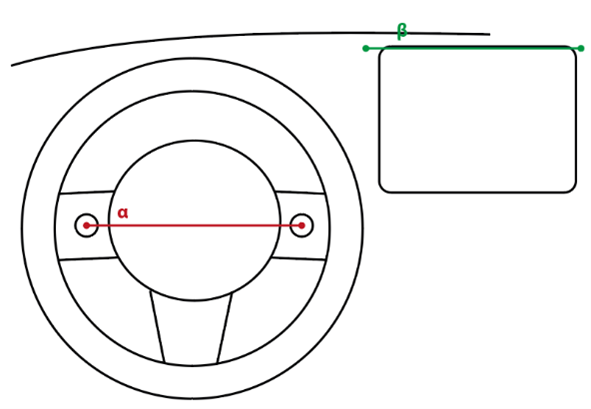

To measure the steering wheel alignment, strategic points of the steering wheel and cockpit area are chosen. For this purpose, specific photos are taken, these points are identified and the steering wheel and cockpit angles are calculated. The difference between these angles must not exceed a specific tolerance indicated by the customer’s quality experts.

Here is a summary of the measurement process:

Cameras and Lighting: High-intensity lights and cameras are positioned to capture precise images of the steering wheel and cockpit area.

Data Collection: As the vehicle moves through the tunnel, sensors activate the system to take multiple images, which are analyzed to measure the steering angle.

3D Positioning: The system calculates the 3D position of key features, like the steering wheel and center console, to ensure perfect alignment.

OEM Integration: The results are sent in real-time to the OEM’s data systems for review and to ensure the correct alignment before moving on to the wheel alignment phase.

This automated system not only saves time but also enhances accuracy, ensuring that all vehicles meet strict OEM standards.

The Risks of Misalignment

Poor steering and wheel alignment can lead to:

- Loss of control: Misaligned wheels reduce your control over the vehicle, making it harder to handle, especially in hazardous conditions.

- Uneven tire wear: Tires will wear out faster and unevenly, leading to vibrations and reducing the lifespan of the tires.

- Uneven brake wear: Misaligned wheels can cause one brake to wear out faster than the other, which compromises the braking system.

Maintaining proper alignment ensures longer tire life, improved fuel efficiency, and enhanced vehicle safety. This is why it’s crucial for manufacturers to detect and correct steering wheel misalignment during the car assembly process.

Why Choose EINES’ Automated Steering Alignment Solution?

- High Precision: The vision-based system detects even the smallest misalignments.

- Automation: Full automation reduces human error and improves efficiency.

- Integration: The system can be integrated with other inspection processes, optimizing time and resources.

- Real-Time Feedback: Data is sent instantly to OEM systems, allowing immediate adjustments.

For automakers, ensuring proper steering wheel alignment before wheel alignment is vital for vehicle quality, safety, and customer satisfaction. The EINES vision-based system makes this process automatic, accurate, and efficient. Reducing errors and ensuring that every vehicle that leaves the production line meets the highest standards.

Integrating this solution into your production line can reduce costs, increase efficiency, and ensure your vehicles are built to perfection.