EINES Vision Systems installs a vision tunnel capable of verifying more than 40 specifications in real time without stopping the line

At Renault Group’s factory in Palencia, where hundreds of vehicles are assembled daily under the highest quality standards, the challenge was clear: ensure the correct installation of multiple components and perform aesthetic checks without slowing down the production line. To address this, Renault relied on the expertise of EINES Vision Systems, a company specialized in artificial vision solutions for quality control in the automotive industry.

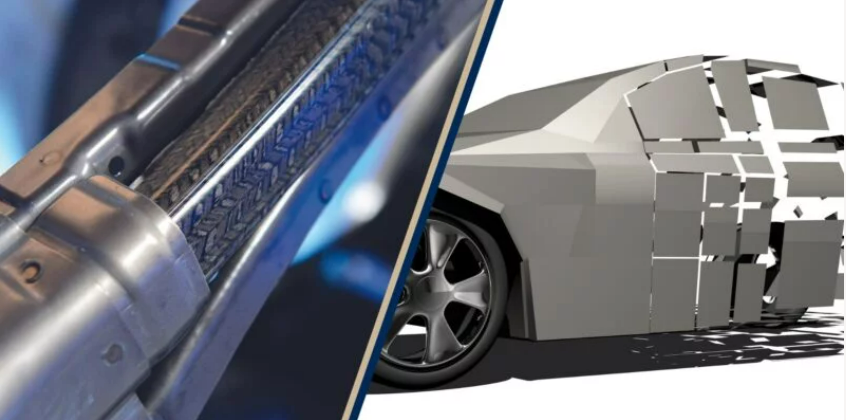

The implemented solution was a fully automated vision tunnel that inspects vehicles in motion, without the need to stop the line — not even during internal inspections performed with open doors. Thanks to its advanced architecture and the use of high-resolution cameras combined with specular lighting, the system is capable of verifying more than 40 specifications simultaneously across different areas of the vehicle, such as the hood, engine bay, doors, trunk, or tailgate.

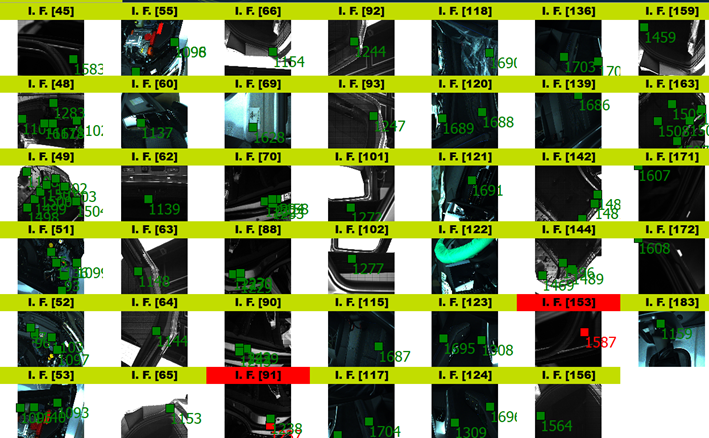

The system checks the presence or absence of key elements such as screws, caps, labels, buttons, or rain sensors, and validates that each component matches the specific configuration of the vehicle in production. This part-to-spec verification ensures there are no assembly errors, misplaced parts, or incorrect components for the model being manufactured.

How does ”Multi Error Proofing” technology work?

At the core of this system is EINES’ patented technology called Multi Error Proofing — a modular image analysis platform that validates multiple types of specifications by combining different visual processing techniques into a single coordinated inspection.

For each inspection point, the cameras capture a high-resolution image of the area or component. This image is analyzed using various validation engines developed by EINES, including:

- Locator (Pattern Recognition) – detects known patterns in the image to identify components or positions.

- HSL Color – searches for specific colors within a defined area, even under variable lighting conditions.

- Blob – detects grouped pixels in specific zones, useful for identifying objects or obstructions.

- Expression – a logic tool that combines multiple conditions to determine specification compliance.

- Color Comparator – compares two color areas in the image to check for match or difference.

- Measure – calculates pixel distances between two points to verify dimensional tolerances.

- AI / Machine Learning – uses trained object detection models to recognize complex or variable elements with high robustness.

Combining all these tools into a single platform enables an extremely versatile inspection, capable of adapting to new models, configuration changes, and engineering updates — all without requiring hardware modifications.

Real-Time Feedback and Continuos Analysis

The system provides instant feedback on screens located at the finish line, enabling operators to take quick and effective corrective actions. Additionally, all collected data is stored and continuously analyzed to detect trends, identify root causes, and prevent future non-conformities. In this way, the tunnel not only inspects — it contributes directly to continuous quality improvement on the production floor.

Impacts and Results

Thanks to the solution installed by EINES, Renault Group’s Factory in Palencia has successfully digitized and automated a critical verification process that traditionally depended on manual operations, with a higher risk of human error. Today, the system not only ensures full traceability for every inspection, but also does so without impacting cycle time — allowing the vehicle to move forward at a normal pace while validating multiple control points in parallel.

This success story demonstrates the value of integrating smart vision systems into complex industrial processes, where precision, efficiency, and flexibility must coexist. The collaboration between Renault and EINES is a clear example of how technology can raise quality standards without compromising productivity.