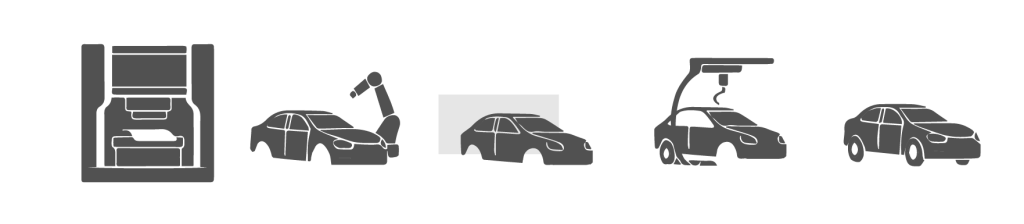

Final Assembly Solutions

Our Metrology Tunnel enables full inline dimensional inspection with no production stop. Using cutting-edge laser and vision technology, it captures thousands of measurement points on moving vehicles to ensure geometry, fit, and alignment meet OEM standards. Reliable, fast, and fully automated—your quality control, streamlined.

Our advanced vision systems are designed to detect surface imperfections such as scratches, dents, and other cosmetic defects during the final stages of production. With high-resolution imaging and AI-powered analysis, we help manufacturers maintain high quality standards, reduce rework, and deliver a perfect finish every time.

Our Metrology Tunnel enables full inline dimensional inspection with no production stop. Using cutting-edge laser and vision technology, it captures thousands of measurement points on moving vehicles to ensure geometry, fit, and alignment meet OEM standards. Reliable, fast, and fully automated—your quality control, streamlined.

Ensures correct specification of wheels, bumpers, side skirts, spoilers or any other optional extras fitted. The vision system provides immediate feedback at the finish line for repair actions.Also we have user-friendly interfaces to check results afterworks.

Our All In One Tunnel combines advanced metrology, component verification, and surface defect detection—such as scratches and dents—in a single, seamless station. Designed for the final stages of automotive production, it ensures that every vehicle meets dimensional accuracy, proper part installation, and flawless surface finish before leaving the line. One tunnel. Total confidence.

You can also search your solution through the different Automotive stages