The Beginning: A Vision in 1992

Eines Vision Systems, founded in 1992, began as a shared dream of five university friends who studied computer science and decided to start a project together. Thus, Eines Informática was born with a clear vision: to apply their knowledge and passion for technology to create innovative solutions. They set up in Carcaixent, a small town in Valencia, Spain, marking the beginning of a growth and success story that continues to this day.

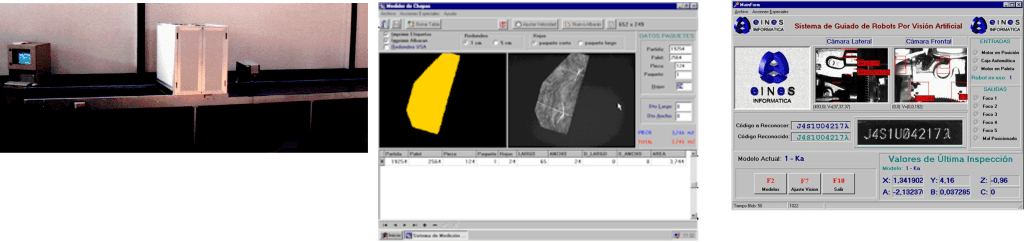

The First Steps in the Automotive Industry

The first few years were focused on experimentation and development, with the company concentrating on customized solutions for its clients. However, it was the automotive industry that truly awakened Eines’ potential. After several years of research and development in machine vision, Eines installed its first vision system at an automotive OEM, aiming to solve quality challenges in vehicle production in Spain.

Adapting to Market Needs and Evolving Solutions

As the client’s needs evolved, Eines adapted and improved its solutions, developing vision systems to address quality issues in automotive production. This dedication to innovation led to Eines winning an award for its vision system for metrology in 2022. This milestone helped propel the company’s expansion throughout Europe, establishing Eines as a leader in the industry.

International Expansion and Growth

Eines’ success in Europe opened the door to international expansion, and in 2003, the company installed its first vision system in North America, creating new opportunities in the global market. The growing need for more research, development, and manufacturing space led Eines to build a new facility in Almussafes, Valencia. This also marked a rebranding of the company to Eines Quality Engineering & Vision Systems to reflect its evolution and focus on advanced quality and vision solutions.

Innovation in Surface Defect Detection and Joining the Konica Minolta Group

In 2013, the company took another significant step by developing new technology for surface defect detection. In 2016, Eines installed its first Paint Surface Inspection System at an OEM three years later, solidifying its leadership in this field. This technology and the company’s growth led to Eines joining the Konica Minolta Sensing group in 2019. As part of the group, Eines gained a new boost for its expansion, particularly in the Asian region, under the new brand Eines Vision Systems—A Konica Minolta Company.

Advancing Gap & Flush Measurement with Stereo Vision

As the automotive industry advanced, so did the demand for faster and more accurate solutions. In response, Eines developed the Stereo Vision Tunnel for gap & flush Measurement, offering a more efficient robotic solution than ever. This system revolutionized how these measurements are performed in automotive production, demonstrating Eines’ ongoing commitment to innovation.

Continuous Growth and Expansion

The company’s growth was so significant that, in 2021, Eines expanded its facilities once again. It separated its offices and showroom from the manufacturing area, creating a larger, more efficient space to continue its research and development efforts.

A Global Leader in Vision Systems for Automotive Quality

Today, Eines Vision Systems employs over 100 people and has over 1,000 installations worldwide. With over 30 years of experience developing machine vision technology for quality control in the automotive industry, Eines continues to offer the expertise needed to help Automotive Manufacturers and Suppliers achieve the highest quality standards. Thanks to its continuous innovation, Eines has positioned itself as a leader in its field, committed to excellence and advanced technology to improve global automotive production.