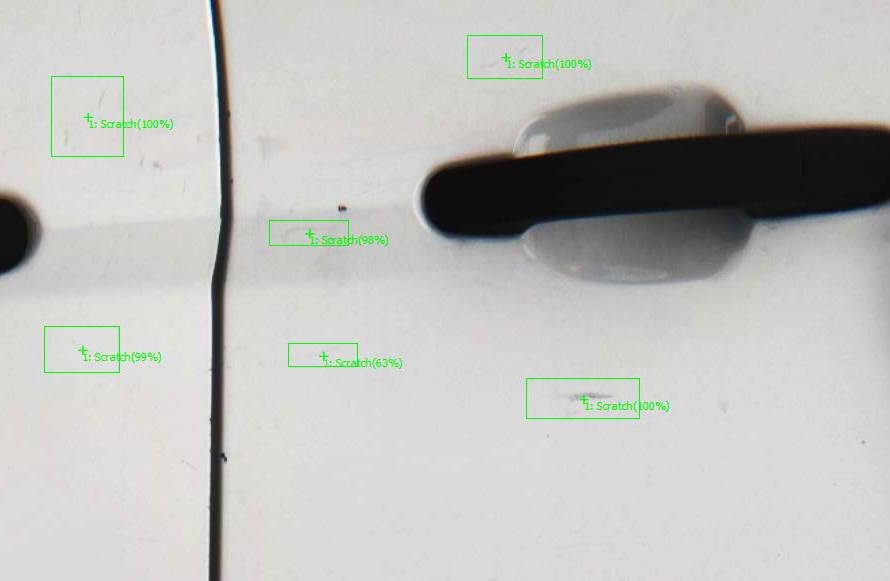

Detection of any type of defect

EINES Paint Tunnel scans all defects in the vehicle surface. The system does a 3D positioning to get the defect’s exact location. It is real-time detection, showing the results right after the vehicle has gone through the tunnel. A variety of report and analysis functions are available to your needs.

- Defect Classification

- Big Data to track and find root causes

- Simple and Sustainable

Listen to our Vision Expert answering technical questions

Only for Automotive Manufaturers

Ask for the entire recording

Artificial Intelligence in Manufacturing

EINES® and Konica Minolta have developed a classification system based on Deep Learning. It can classify the defects into different groups such as flat, fibre, convex, concave, scratch, drop, bump and dent.

Industry 4.0 in Paint

- Precise Defect Detection & Positioning

- Defect Categorization: Thanks to Deep Learning and Artificial Intelligence (AI)

- Defect Repair interface: Paint defects are prioritized, and the best parameters to repair are sent to the robot

- Auto-Repair Robot repairs the vehicle defects

Functions

Scanning Simulation

Multi-Frame Error Detection

Defect Positioning

Defect Categorization

100% Inline Measurement

Data Analysis and Storage

Traceability and Executable Actions

Reporting and Big Data

Remote Assistance 24 Hours

We will adapt to your needs at any place in the world thanks to our assistance team.

Our Customer Success Service is focused on promoting a proactive work culture in partnership with our customers. The purpose is to help you as a customer and end user to get more value out of your purchase and stay in close contact with us to share feedback about the installation.