EINES Vision Systems installs a metrology tunnel with stereo vision technology and part-to-spec verification on a moving vehicle at Renault Group Factory in Palencia

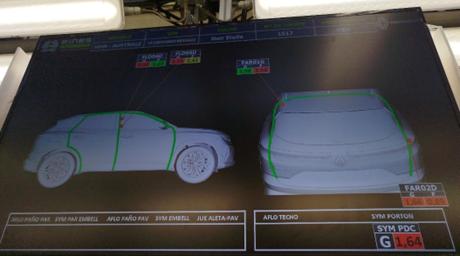

In its constant pursuit of excellence and process digitalization, the Renault Group Factory in Palencia has once again trusted EINES Vision Systems to automate a key stage of assembly quality control: the precise measurement of gap and flush, along with the visual validation of aesthetic and functional specifications. To achieve this, a next-generation metrology tunnel based on EIFIS technology (EINES Inline Gap & Flush Inspection System) has been implemented, integrating two powerful technologies into a single system: Stereo Vision and Multi Error Proofing.

This tunnel operates with the vehicle in motion, without interfering with cycle time, and is capable of performing three-dimensional measurements on hundreds of vehicle sections while, in parallel, verifying that external elements such as logos, trim pieces, wheels, antennas, or emblems are correctly positioned and correspond to the vehicle model.

A Hybrid Metrology + Specification Verification System

The EIFIS tunnel represents a technological breakthrough by combining advanced metrological capabilities with automated visual inspection. Thanks to high-resolution cameras and specular lighting, the system captures both the vehicle’s geometry and the visual details necessary to validate the correct installation of visible elements.

The metrology portion relies on Stereo Vision technology, which uses calibrated pairs of cameras to capture extremely precise stereoscopic images. From these images, the system reconstructs a 3D point cloud of the vehicle’s surface, which is then correlated with the CAD model of the car. This comparison identifies the measurement zones defined by engineering and calculates the exact values of gap (separation between parts) and flush (height difference between surfaces).

These measurements are evaluated automatically according to customer-defined tolerances, ensuring comprehensive assembly quality control without physical contact or manual intervention.

Part-to-Spec Verification with Multi Error Proofing

In addition to dimensional measurements, the tunnel incorporates EINES’s Multi Error Proofing (MEP) system to validate part-to-spec. This module can detect the presence, absence, or misplacement of exterior components, ensuring consistency with each unit’s specific configuration.

Multi Error Proofing technology analyzes each captured image using a set of validation engines, including:

• Pattern Recognition (Locator) to identify parts and their correct position.

• Color Detection (HSL Color) to validate specific finishes or decorations.

• Distance Measurement (Measure) to confirm the alignment of certain elements.

• Color Comparison (Color Comparator) to verify chromatic matching.

• Advanced Logic (Expression) that allows combining conditions to detect complex errors.

• Machine Learning Algorithms (AI / Machine Learning) to detect variable or non-deterministic objects.

Integrating both modules—metrology and part-to-spec verification—in the same tunnel enables a much more comprehensive quality control in a single station, optimizing space, reducing time, and guaranteeing repeatable results.

Immediate Feedback and Predictive Analysis

Inspections are performed in real-time, and results are displayed immediately on monitors installed at the finish line, allowing for a rapid response to any detected deviation. All generated data is collected and analyzed systematically to identify trends, find root causes, and promote corrective or preventive actions.

Thanks to this solution, the Renault Group Factory in Palencia has improved its early error detection capability, reduced rework costs, and raised the standard of final finish quality.

Benefits and Results

With this implementation, the Renault Group Factory in Palencia has achieved a qualitative leap in final vehicle inspection. Automatic gap & flush measurement, directly aligned with CAD models, has enabled dimensional deviations to be detected from the very first units, improving the vehicle’s visual fit and reducing rework. At the same time, part-to-spec verification ensures the correct customization and assembly of exterior elements according to each production variant.

All of this is carried out without stopping the line or affecting cycle time, making the EIFIS tunnel a key tool for guaranteeing quality, efficiency, and flexibility in highly demanding production environments.