Pioneering Progress in the Evolution of Automotive Wheel & Tire Quality Control Processes and Challenges

Challenges and Their Impact on the Production and Manufacturing of Wheel and Tire: Effects on the Automotive Industry

The production and manufacturing of Wheel and Tire, fundamental pillars of the automotive industry, face a series of challenges that threaten the quality and reliability of these essential components. Let’s delve into the specific problems and their impact on the production process:

1. Guaranteeing Tire and Wheel Quality:

- Issue: The presence of defects in tires and wheels, such as design irregularities, incorrect dimensions, or issues with the tread pattern, compromises vehicle safety and customer satisfaction.

- Impact: These defects can result in car accidents, material damage, and personal injuries. Additionally, they lead to warranty claims, additional repair costs, and a negative reputation for the manufacturer.

- Solution: We introduce the EINES Wheel and Tire Inspector, a robust system capable of conducting comprehensive visual and dimensional inspections. By meticulously scrutinizing each component, this solution ensures compliance with design standards, thus mitigating the risk of defects and enhancing product quality.

2. Precision in Component Assembly:

- Issue: Incorrect assembly of components, such as faulty valve insertion in tires or improper rim loading, leads to performance and safety issues in the vehicle.

- Impact: These problems affect vehicle stability, maneuverability, and comfort, potentially resulting in poor driving experiences, increased fuel consumption, and additional maintenance costs.

- Solution: The EINES Robot Guide solution emerges as a beacon of precision in component assembly. Whether it’s flawlessly inserting valves or precisely loading rims, this technology guarantees smooth execution, strengthening product reliability and safety standards.

3. Part Identification during Wheel Balancing:

- Issue: Incorrect part identification during the wheel balancing process leads to the installation of incompatible or defective components.

- Impact: This can cause premature component wear, braking or steering system failures, and even endanger the safety of vehicle occupants, resulting in significant repair costs and potential loss of life.

- Solution: Leveraging years of experience in tire and wheel inspection, the EINES Part Identification system excels in accurately identifying components during production. This meticulous process ensures the installation of the correct parts, minimizing performance discrepancies and safety risks.

4. Verification of Component Presence or Absence:

- Issue: The absence of important components, such as a spare label, and the presence of incorrect or defective components can have serious safety and legal consequences.

- Impact: These issues can result in car accidents, fines for safety regulation non-compliance, legal actions for injuries or damages, and damage to the brand’s reputation, negatively affecting sales and customer loyalty.

- Solution: The EINES Error-Proofing system acts as a vigilant sentinel, meticulously verifying the presence or absence of various components. By minimizing assembly errors and ensuring regulatory compliance, this system strengthens product integrity and safety standards. Additionally, its adaptive artificial intelligence capabilities allow for seamless configuration of new component checks at any time.

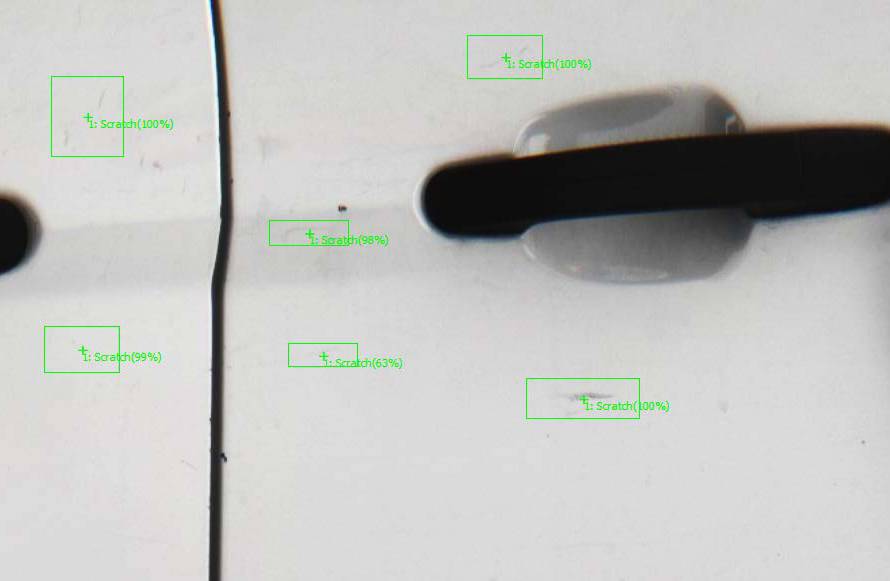

5. Custom Vision Solutions for Enhanced Quality Control:

- Challenge: Conventional quality control methods may lack the agility and precision required to navigate the complexities of modern manufacturing processes, leading to inefficiencies and quality lapses.

- Solution: We present EINES Vision Systems, armed with customized solutions tailored to the unique demands of each manufacturing plant. Leveraging cutting-edge technologies such as deep learning, machine learning, and computer vision, our solutions offer millimeter-level precision and efficiency in quality control. By elevating overall product quality and safety, EINES Vision Systems propels the automotive industry towards unprecedented levels of excellence and innovation.

In summary, the challenges in the production and manufacturing of Wheel and Tire have a significant impact on vehicle safety, quality, and reputation. It is essential for manufacturers to implement effective quality control measures and adopt innovative technologies to address these issues and ensure excellence in the manufacturing of these critical components.

EINES Vision Systems solutions for Wheels and Tires embody excellence in innovation, successfully addressing the multifaceted challenges inherent in automotive manufacturing. By combining advanced technological prowess with unwavering commitment to quality standards, we empower manufacturers to overcome obstacles and chart a course towards a future defined by unparalleled excellence and innovation.