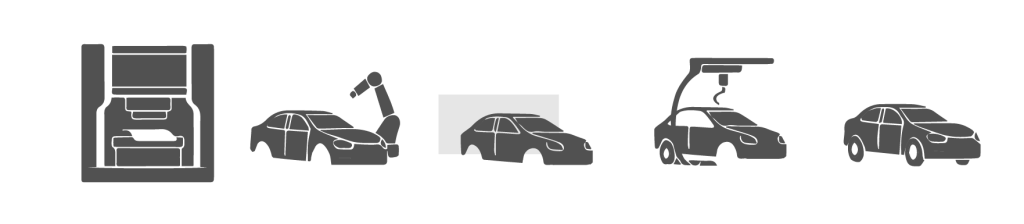

In-line Vision Tunnels

Spec Check Tunnel

for part-to-spec control based on Multi-Error Proofing Technology

Paint Inspector Tunnel

for detecting paint surface defects on automotive bodies using AI technology

All in One Tunnel

for performing 3 inline inspections in only one system

Damage Inspector

for detecting damage on the car bodies surface like scratches or dents

Parts Inspection

MEP Cabinets

Automatic or semi-automatic cabinets that checks Interior and Exteriors components

EH2 Handheld

Metrology handheld which helps to measure the gap and the flush of the surface of the car

Welding Check

Detects and inspects welds on the car to ensure proper bonding, structural strength , and compliance with safety standards.

Press Shop

Inspect stamped metal parts to detect surface defects, dimensional deviations to meet quality standards before assembly.

Glazing Solution

Ensures the correct installation and sealing of vehicle glass components, guaranteeing visibility, structural support, and protection from external elements.

Sealer Check

Sealer Check verifies the proper application and integrity of sealants on vehicle components to prevent leaks and ensure durability.

Wheel & Tire Inspection

DOT Reader

Checks the DOT code on your tire to ensure its age and safety compliance.

Rim Inspection

detects surface defects such as cracks, corrosion, or dents on the wheel rim.

Labeling Control

Ensures that all required labels on the wheel are present, correctly positioned, and legible.

Valve Insertion

Ensures the valve is correctly positioned and securely installed in the wheel for optimal air retention and safety.

Other Solutions

EV Battery

EV Battery inspection ensures the quality, safety, and performance of electric vehicle batteries through thorough testing and defect detection.

Operator Guidance

Operator Guidance provides real-time instructions and feedback to workers, ensuring correct task execution and improving overall production quality.

3D Guidance

3D Guidance systems provide precise spatial positioning and alignment during manufacturing processes, improving accuracy and efficiency

You can also search your solution through the different Automotive stages

Previous slide

Next slide