When building a vehicle, we often focus on visible elements like paint, design, or technology. But behind the scenes, seam sealant quietly plays a vital role in protecting a car’s long-term quality. The question is not whether to apply sealant, but how well it’s applied.

So… What happens when the sealant is applied poorly or inconsistently? The answer: costly failures, avoidable rework, and unhappy customers. Let’s explore why controlling sealant quality is essential, and how automated inspection systems can help manufacturers avoid critical risks.

Isn’t applying sealant enough?

Not really. Applying sealant is just the beginning. Applying it correctly is where the real value lies. Seam sealant is responsible for sealing gaps and joints between body panels to prevent moisture, air, and dust from entering. This helps prevent corrosion, noise, and water leaks, all of which impact vehicle performance and customer satisfaction.

However, when sealant is applied inconsistently, such as being too thick, too thin, off-path, or with missing sections, the protection fails. Water can seep into welded joints through capillary action, causing rust from the inside out. Over time, this can damage structural components and require expensive repairs.

What are the risks of poor sealant application?

Here are just a few:

- Corrosion and rust in seams, especially in high-humidity climates

- Water leaks that compromise electronics or upholstery

- Reduced paint durability, due to exposure from unsealed joints

- Higher maintenance costs, warranty claims, and production downtime

- Loss of OEM quality reputation

In short: the sealant may be invisible to the customer, but its impact is impossible to ignore.

How can manufacturers ensure every application is perfect?

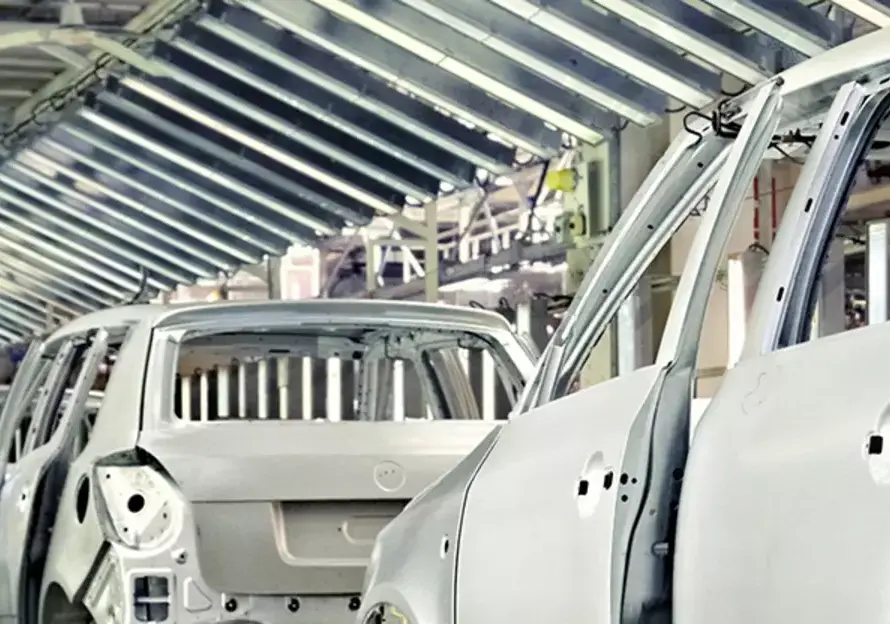

Relying solely on manual or visual inspection is insufficient. Even the most skilled workers or robots face limitations in consistency, especially on fast-moving production lines. That’s where automated quality control systems, like those developed by EINES, come into play.

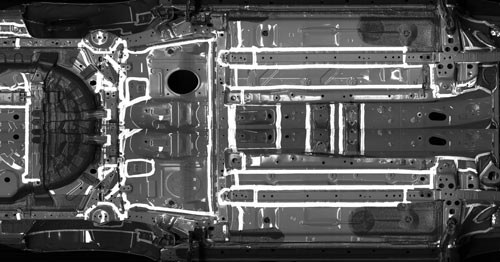

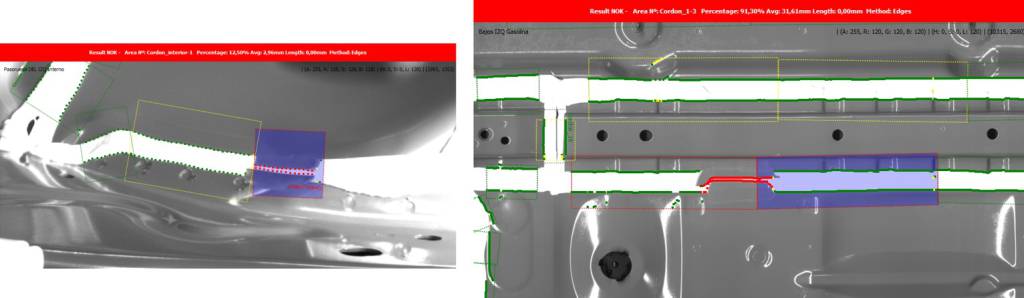

EINES Sealer Check System integrates directly into the production line, using multiple cameras to inspect the sealant bead from various angles. It verifies presence, continuity, width, thickness, and alignment in real time. Thanks to its intuitive configuration wizard, the system adapts quickly to different part types and paths—no vision engineering expertise required.

What makes this system truly powerful is its combination of precision, speed, and data intelligence. It performs high-speed inspections, ensuring 100% coverage without slowing production. All results are stored and visualized through dashboards for full traceability, trend analysis, and root cause identification. This enables manufacturers to proactively prevent defects and maintain a consistently high standard of sealant application across all vehicles.

Know more about EINES Sealer Check >>

Can automation help improve overall vehicle quality?

Absolutely. Consistent and high-quality sealant application improves:

- Durability of structural components

- Resistance to noise and vibration

- Paint adhesion and uniformity

- Thermal and moisture insulation

- Customer satisfaction over time

By integrating automated inspection, you’re not just avoiding defects, you’re adding long-term value to your vehicles.

Is it time to rethink your sealant inspection strategy?

If you still rely on manual quality checks or partial sampling, you might be missing hidden defects and opportunities for improvement.

At EINES, we help automotive OEMs and Tier 1 suppliers implement automated inspection solutions that are fast, precise, and fully traceable. Our vision systems operate in real-time, integrate seamlessly into existing lines, and provide complete control over the quality of each bead.

Ready to take seam sealant quality to the next level? Let’s talk. Whether you want to reduce rework, increase consistency, or safeguard your vehicle’s reputation, we can help you achieve your goals.

👉 Contact us >> to request more information.