Ensuring Perfection in Automotive Panel Inspection

The quality of instrument panels in the automotive industry is a fundamental aspect that directly impacts customer satisfaction and brand reputation. However, manufacturers of these components face a series of technical challenges in production processes, especially regarding quality control. For this reason, we will explore in detail the specific problems faced by these manufacturers. We will give potential solutions to address them effectively supported by relevant data and figures.

Analysis of Materials and Manufacturing Processes

Despite technological advancements, material and manufacturing process analyses remain a critical point. Society of Automotive Engineers (SAE) debates that up to 30% of quality problems in instrument panels are related to defects in materials or manufacturing processes.

Specific Challenge: Lack of detailed analysis can result in the use of defective materials or inadequate processes. As a consequence, this could lead into compromising the quality of the final product.

Implementation of Advanced Technologies

Although additive manufacturing and computer simulation offer significant advantages, their effective integration remains a challenge. International Organization of Motor Vehicle Manufacturers (OICA) says that only 40% of instrument panel manufacturers have fully implemented these technologies in their production processes.

Specific Challenge: Lack of personnel training and insufficient investment in technological infrastructure can hinder the successful implementation of these technologies. And, as a resut, limits their impact on the quality of the final product.

Assembly and Finishing

Control of dimensional tolerances during assembly remains a critical challenge. In opinion of internal data from leading manufacturers, up to 15% of instrument panels are rejected during final inspection due to fit and finish issues.

Specific Challenge: Lack of control in dimensional tolerances can result in fit and finish problems, negatively impacting the appearance and functionality of the instrument panel.

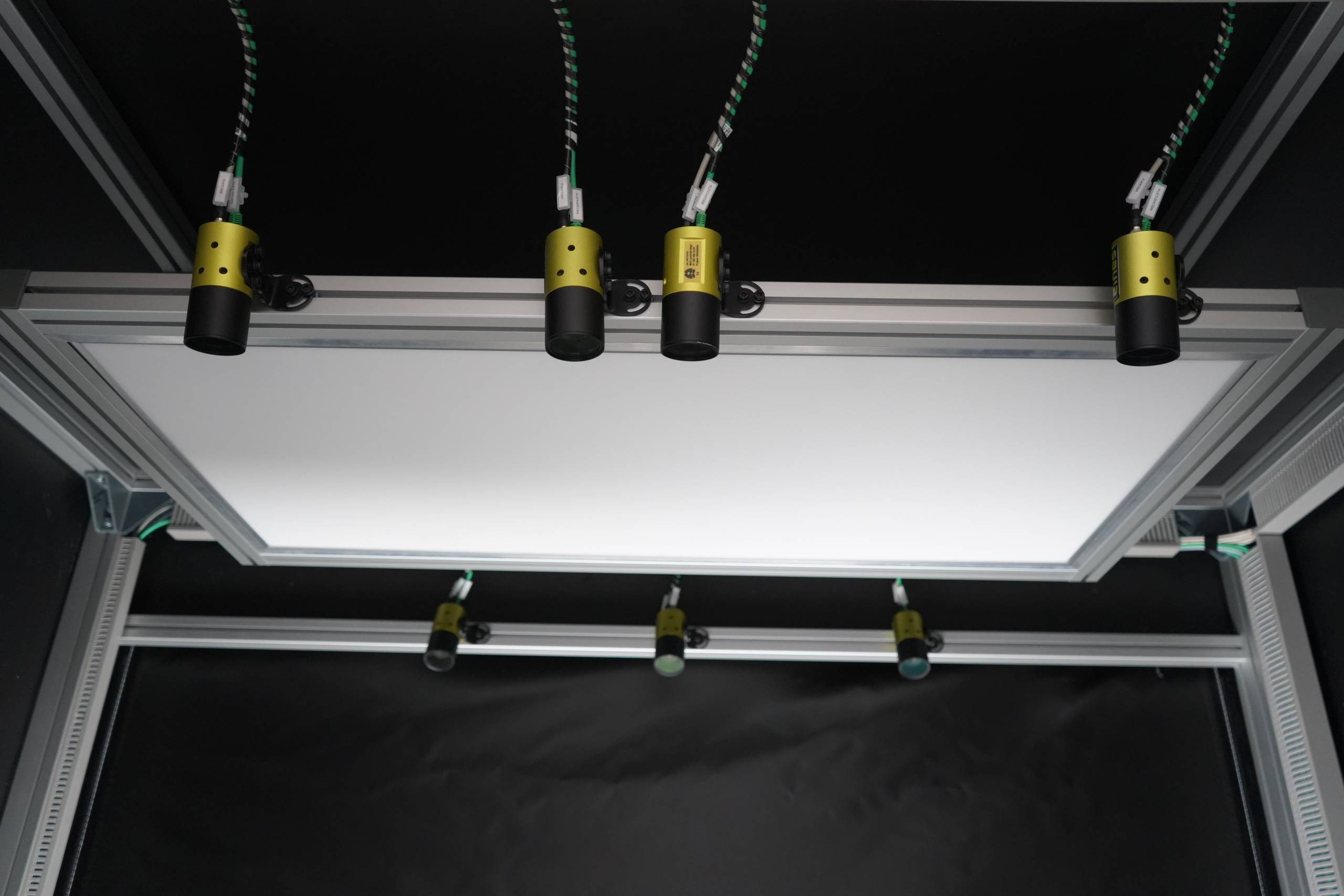

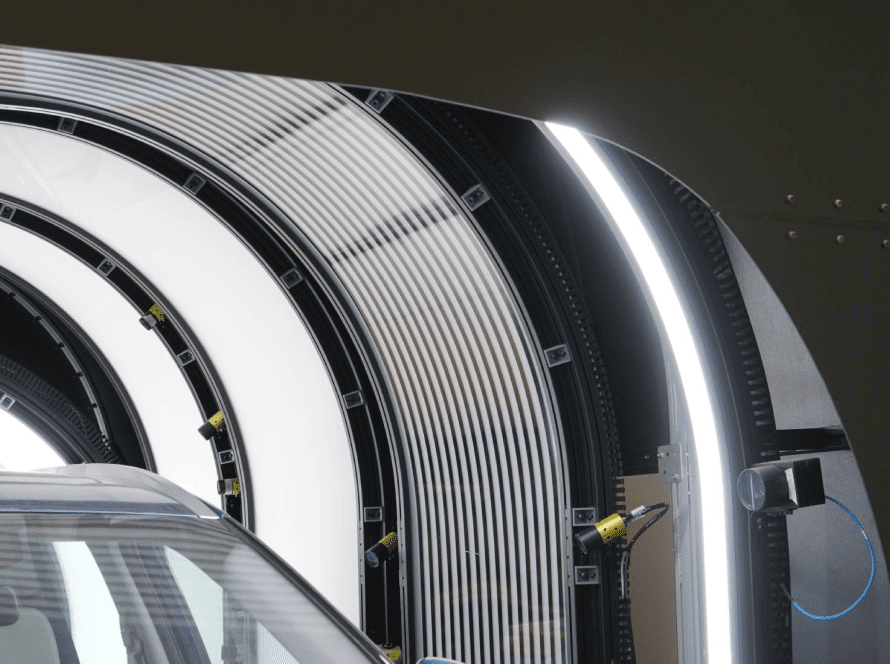

Visual and Dimensional Inspection

Lack of advanced inspection tools remains a significant limitation. According to data from the International Automotive Task Force (IATF), only 50% of instrument panel production plants use automated inspection systems.

Specific Challenge: Lack of advanced inspection tools and trained personnel can hinder the accurate detection of defects, compromising the quality of the final product.

Functional and Durability Testing

Functional and durability testing still face challenges in accurately simulating real-world usage conditions. According to data from the National Highway Traffic Safety Administration (NHTSA), 10% of performance issues reported in instrument panels are related to deficiencies in durability testing.

Specific Challenge: Lack of accurate simulation of real-world usage conditions and thorough verification of component functionality can result in performance and safety issues with the final product.

Towards Enhanced Automotive Instrument Panels Quality

In conclusion, it’s crucial to consider effective solutions. Suppliers and manufacturers of automotive instrument panels face specific technical challenges in quality inspection, which can affect the reliability and durability of these critical components.

To address these issues, it is vital to implement innovative technologies and rigorous quality management systems. By understanding these challenges, the automotive industry can improve the quality and safety of automotive instrument panels.

To gain further insights and explore cutting-edge approaches, we extend our invitation to our online seminar and masterclass:

Stay at the forefront in Automotive Interior Parts Quality Control.

Reserve your spot today through the link/button below.

Link

Don’t miss out on this opportunity to enhance your understanding and expertise in this critical area.

Limited slots available*.

Sources

Society of Automotive Engineers (SAE): https://www.sae.org/International

Organization of Motor Vehicle Manufacturers (OICA): https://www.oica.net/

International Automotive Task Force (IATF): https://www.iatfglobaloversight.org/

National Highway Traffic Safety Administration (NHTSA):https://www.nhtsa.gov/

These organizations provide key information on standards, regulations, and developments in the automotive industry, which are essential for understanding the challenges and advances in automotive manufacturing and its derivatives.