The other day, during a discussion about Artificial Intelligence with people specialized in the subject, a question arose that, despite being very simple, lends itself to quite an extensive debate.

What we know about Artificial Intelligence?

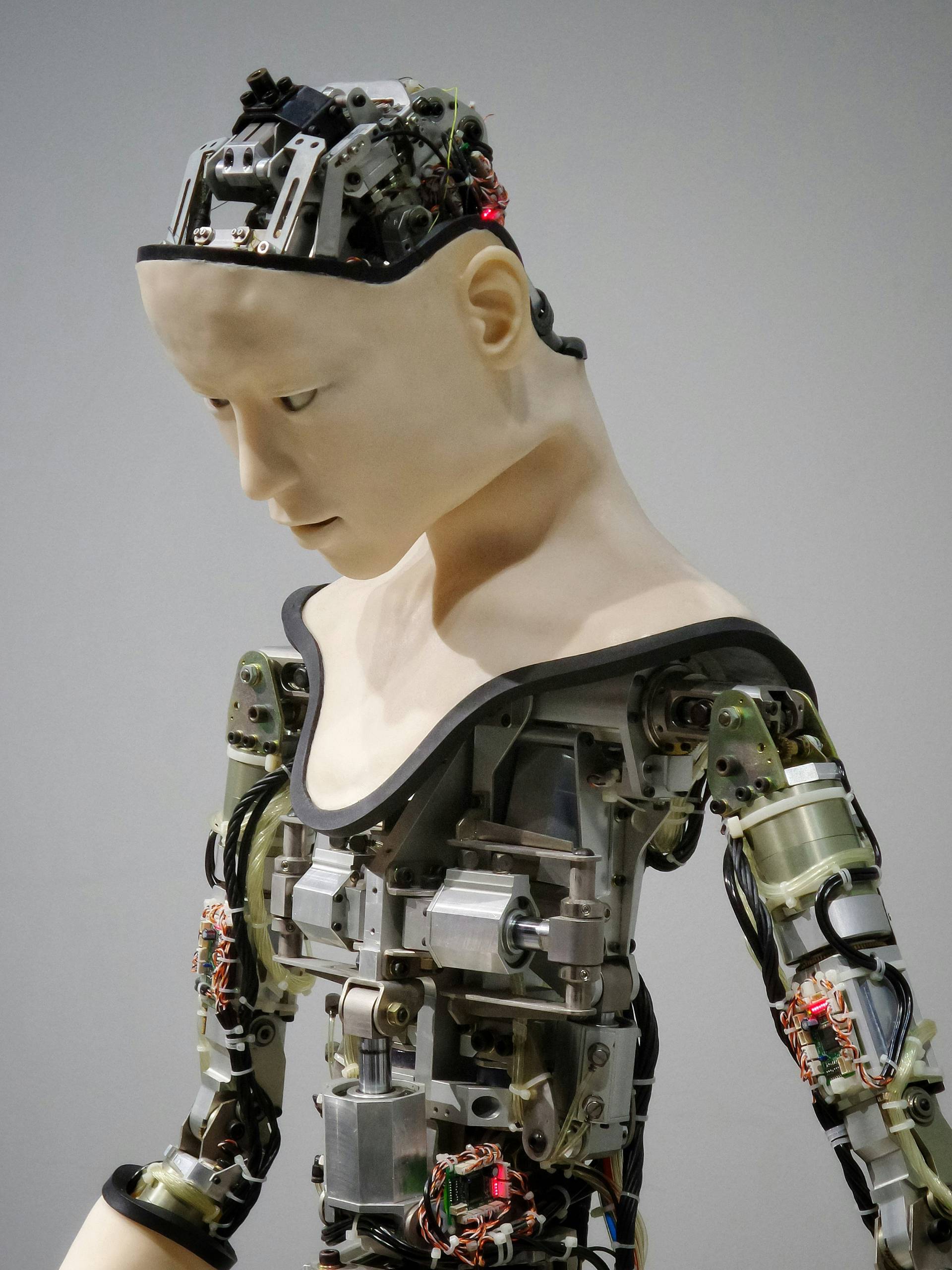

Nowadays, we all know what artificial intelligence is and how it has been advancing and gaining momentum disproportionately in recent years. We know it is a useful tool for many areas of life, whether in medicine, law, and, of course, in industries like ours, which is automotive. But those people interested in buying such solutions and adapting artificial intelligences, do they really know how they work? Or do they simply understand the concept of artificial intelligence without knowing the depth involved in using such solutions? Or even, the level of expertise required by all those who dedicate themselves body and soul to these configuration tasks?

This is the key point of this blog today. To explain, in broad terms, how these tools work, how we implement them in our systems, what they actually do, and what people imagine they do. Because yes, we often encounter mistaken or exaggerated ideas about what this new tool is capable of doing.

Artificial Intelligence knows how to do everything…or not?

That a machine operates with artificial intelligence does not mean it knows how to do everything, much less that it can assess and decide like a human being. We specialize in the world of quality control for the automotive sector, creating booths and tunnels capable of identifying defects on surfaces, the absence or presence of elements, and much more…

Many times, people say to us: “If my eye can see it, your camera should be able to, right?” As human beings, the intrinsic ability we have to learn is much more plastic than a computer. In the end, we rely on the fact that everything is, after all, software and programming based on image training. It cannot help or solve any problem for which it has not been previously trained. But answering your question – if you’ve asked it – yes, it could see everything with a good base of examples. And of course, for that, there are people behind all these solutions dedicated to developing artificial intelligence as we understand it today.

Correct and incorrect

So, with all this said, how does artificial intelligence work? The process of training a model can be complex… or not (depending on the requirements). For example, to create a defect detection network must be understood that is based on what one defines as correct and incorrect. These kinds of tools leave no room for subjectivity (an advantage), but it’s also essential to define very clearly what we, as clients, consider acceptable and what we consider unacceptable. The machine itself will not decide this; it relies on a large number of labeled, trained, and studied images to determine classification. The complexity in these cases lies mostly in the human decisions about what to approve or reject.

Nothing is more precise and objective than a machine

We could even consider that the machine’s potential inconsistencies stem from human doubts or flexibilities. Nothing could be more precise and objective than a machine, but it’s not made for subjectivities. We must keep this in mind.

To train all those images properly, we need a specialized team of artificial vision experts with years of experience to meet all the requirements we seek. This is how we achieve the excellence we hope for when purchasing such a system.

Therefore, to summarize, as a company that creates some artificial intelligence solutions, communication between people for training neural networks (an Artificial Intelligence) is almost more important than the simple fact of creating the solution itself, even after 30 years of experience.

Different levels of demand

Not to mention that it must satisfy all levels of demand within an automotive company. Broadly speaking, we could differentiate three types of interest: that of the director, the project manager, and the operator. For a solution of this type to work properly in a plant, it must gain approval, to a greater or lesser extent, from each of these levels. The director wants results and reports; the project manager knows what is needed in a factory and what would work well; and the operator, who is on the factory floor, has significant experience in quality control due to daily practice.

Artificial intelligence is one thing, but not all companies are prepared to satisfy the various hierarchical levels. This, like any expertise, is achieved through years of challenges and experiences in different countries. Culture is also a point to consider and can influence the way of working. Again, that expertise we often talk about is necessary.

Conclusion

Today, our machines are trained – and let me say, with quite positive feedback – to perform their work exceptionally. But, as in all business-to-business (B2B) relationships, honesty is the basis of understanding. We would like to pose a few questions to the audience to see what you think (or at least to spark some reflection): Is artificial intelligence the turning point of a new era? Not only for quality control but also for determining what is right and what is wrong? Could it replace us in the essentials or only in the most repetitive tasks?