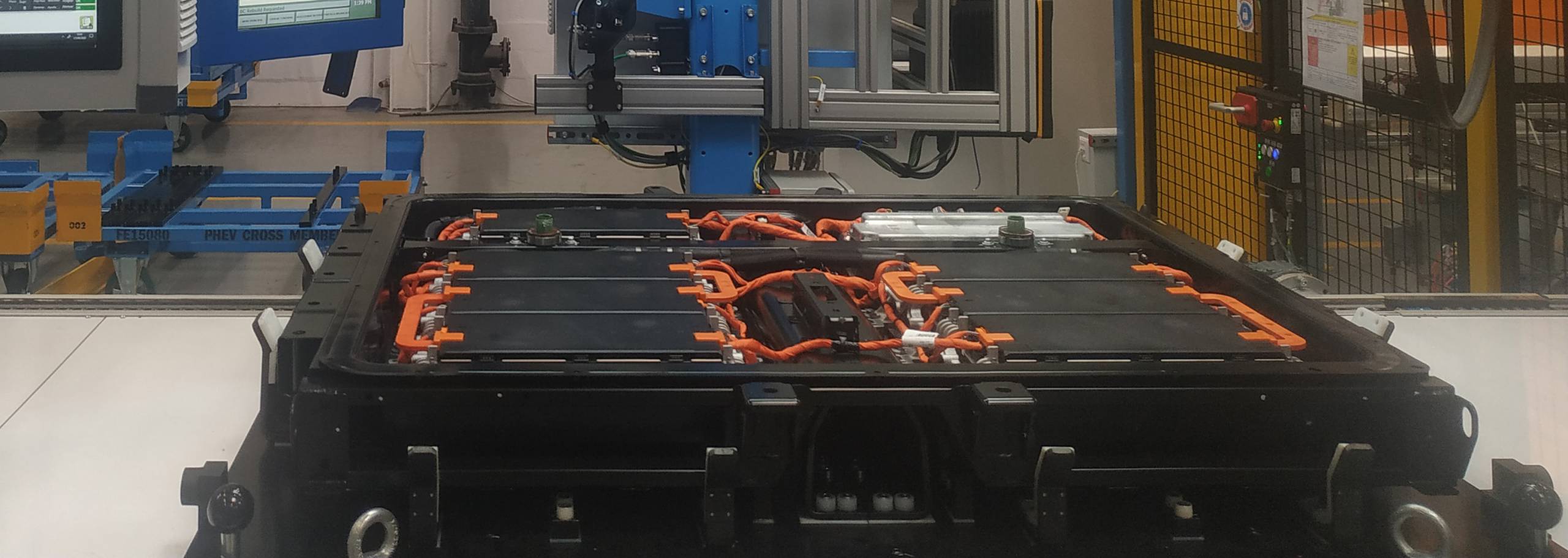

Innovative Solutions for Battery Manufacturing Challenges

Technological Innovation to Overcome Challenges in Automotive Battery Manufacturing

The accelerated growth of the electric and hybrid vehicle market has positioned battery manufacturing as a crucial element within the Automotive Industry. However, this boom has also given rise to a series of challenges. These challenges that must be addressed with precision and effectiveness to ensure the quality and optimal performance of essential components.

In this article, we will explore in detail the challenges inherent in battery manufacturing. Also, how EINES VISION SYSTEMS EV Battery Inspector technology is revolutionizing the way these obstacles are faced and overcome.

Challenges in Automotive Battery Manufacturing:

1.Uniformity of Quality in Cell Assembly

Maintaining uniformity in the quality of individual cells is essential to ensure consistency in battery performance and durability. However, variations in chemical composition and electrode thickness can compromise the quality of the final product.

2. Hermeticity and Sealing of the Battery Pack

Ensuring the hermeticity and proper sealing of the battery pack is crucial to prevent leaks of electrolyte fluid and protect the integrity of the component. The lack of effective sealing could result in serious damage and even jeopardize vehicle safety.

3. Charge Distribution and Internal Resistance

Optimizing charge distribution among cells and minimizing internal resistance of the battery pack are fundamental aspects to improve vehicle performance and energy efficiency. However, uneven charge distribution could negatively impact energy storage capacity and battery life.

4.Precision and Reliability of Quality Tests

Ensuring the precision and reliability of quality tests is essential to detect possible defects or anomalies in cells and the battery pack. Early detection of any issues during testing is crucial to avoid the production of defective batteries, which could compromise brand safety and reputation.

Solutions with EV Battery Inspection Technology

Our EV Battery Inspector technology offers advanced and effective solutions to address these issues:

1.Precise and Rigorous Process Control

This technology enables the implementation of precise and rigorous manufacturing processes. Minimize variations in cell quality and ensures uniform performance across the production line.

2.Advanced Sealing and Testing Technologies

With advanced inspection and testing functions, EV Battery Inspector technology ensures hermetic sealing and conducts comprehensive quality tests at all stages of the production process. This guarantees the integrity and reliability of the battery pack.

3. Real-Time Monitoring and Data Analysis

Through real-time monitoring and data analysis systems, the technology allows for proactive identification and correction of quality issues. In result, it continues improving manufacturing processes and the quality of the final product.

EV Battery Inspector technology is leading a revolution in automotive battery manufacturing.

And…How? Offering innovative and effective solutions to address critical process challenges. As well as by providing precise and rigorous control, advanced sealing and testing technologies, and real-time data analysis. This technology is paving the way for excellence in battery manufacturing, driving the electrification of transportation towards a more sustainable and efficient future.