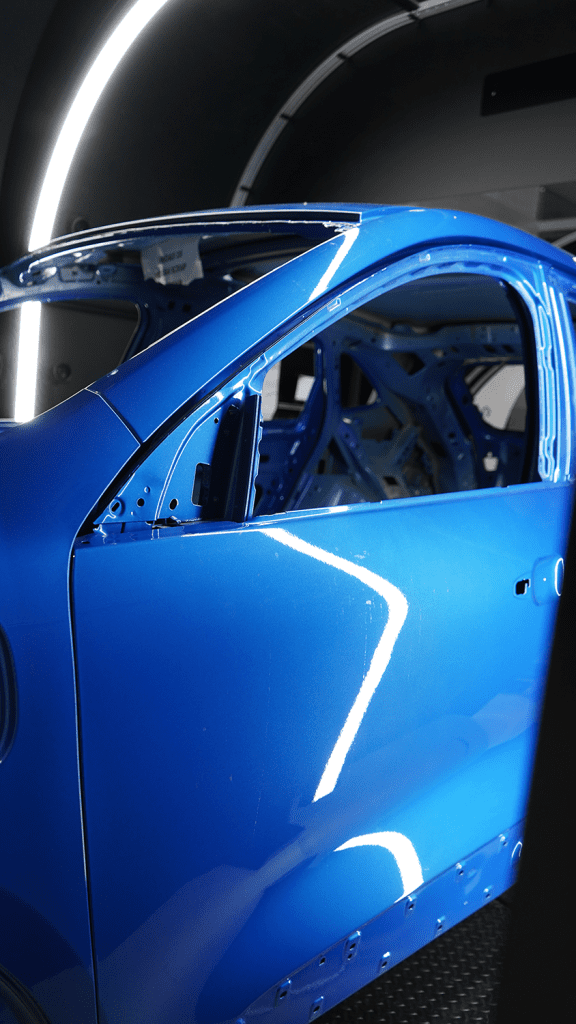

Achieving consistent paint quality in the automotive industry is not optional — it’s a strategic requirement.

From showroom presentation to customer delivery, a car’s surface finish reflects brand excellence, attention to detail, and precision engineering. However, ensuring consistent surface quality is a complex challenge.

That’s where ESFI (Eines Surface Paint Quality Inspector) steps in — a fully automated, AI-based paint inspection system designed for real-time detection of surface defects with unmatched accuracy and reliability.

If you’re new to ESFI, here’s what you need to know:

ESFI combines LED lighting, high-resolution vision, and deep learning models to detect, locate in 3D, and classify automotive paint defects. Installed immediately after the paint booth or curing oven, ESFI enables non-stop, inline inspection, identifying all types of paint surface imperfections.

It seamlessly integrates with your MES or Quality Management System (QMS), providing full traceability, data visualization, and actionable insights.

ESFI helps OEMs and Tier 1 suppliers improve paint inspection performance, reduce scrap and rework, and speed up production. Whether you’re inspecting full car bodies or individual parts (bumpers, mirrors, handles), ESFI adapts automatically.

Reasons Why ESFI Is a Game-Changer in Automotive Paint Quality Control:

- Fully Automated and Objective Surface Inspection

ESFI eliminates human variability by applying the same inspection standards 24/7 — ensuring high repeatability and precision without human validation. - Improved Surface Quality and First-Time Quality (FTQ) Rates: Early defect detection means only flawless vehicles move forward. This improves FTQ and minimizes customer returns or end-of-line rework.

- Lower Rework and Paint Waste Costs: Catching defects in real time allows teams to respond before defects cure, saving paint materials, energy, and manual labor.

- AI Trained with Real Paint Defect Scenarios: Machine learning models trained on thousands of examples guarantee high classification accuracy — even with complex geometries and metallic paints.

- Multi-Model and Color Compatibility: Whether switching from SUV to sedan or black to white, ESFI auto-adjusts inspection parameters, making it ideal for mixed-model production lines.

- Real-Time 3D Defect Mapping for Robotic or Manual Repair: ESFI instantly delivers data on defect type, 3D location, contour, and severity — usable in robotic paint repair systems or guided manual correction.

- Modular Design for Easy Paint Shop Integration: Its compact, modular architecture fits within existing plant layouts without disrupting takt time or requiring major infrastructure changes.

- Supports Predictive Maintenance and Process Optimization: ESFI tracks defect trends over time, identifying root causes and optimizing painting processes through predictive analytics.

- Boosts Line Efficiency and Paint Shop Throughput: Inline, real-time inspection avoids bottlenecks and keeps your KPIs aligned — all while accelerating cycle times.

- Enhances ESG and Sustainability Initiatives: Less rework means lower energy consumption, CO₂ emissions, and material waste — supporting your company’s sustainability and ESG targets.

Ready to Modernize Your Automotive Paint Inspection Process? Each plant is different — and so is every paint line. We conduct custom ROI studies to assess the benefits of integrating ESFI into your system, considering:

- Current inspection workflows

- Line speed and cycle time

- Plant layout and equipment space

- Number of vehicle models and paint colors

- Required inspection coverage and accuracy levels

Let’s explore your specific case.

Contact us today to discover how ESFI can help you achieve perfect paint finishes, reduce operational costs, and lead the way in automotive surface inspection