What is eMEP EOL?

eMEP EOL is an inspection system based on artificial vision technologies such as computer vision and artificial intelligence, designed to ensure the presence, position, functionality, and quality of critical automotive exterior and interior vehicle components such as headliners, door panels, instrument panels…

Installed at the end of the car manufacturing plant‘s production line (EOL), this smart system enables 100% automatic* and semi-automatic** inspection, ensuring every manufactured unit meets the highest standards of quality control in the automotive industry.

In an industry where quality standards are extremely demanding, recalls can severely impact Tier 1 suppliers, both in terms of reputation and financial cost. OEMs expect flawless quality, and in cases where defective parts are delivered, Tier 1 suppliers may be required to cover significant penalties or compensation fees. Ensuring total quality control is not only essential to meet customer expectations but also to protect business continuity and long-term partnerships in such a competitive and high-stakes environment.

The challenges of manual inspection

Traditional manual inspection methods present serious limitations:

- They detect only up to 80% of actual defects (Sandia National Labs, 2012).

- Results are operator-dependent and affected by fatigue and repetition.

- There is no traceability—only the inspector’s judgment remains.

eMEP EOL overcomes these challenges through automated vehicle inspection systems that offer objective and fully traceable inspection.

Key advantages of the MEP EOL system

- Powerful and precise automated car production inspection: detection of clips, nuts, seams, logos, buttons, lighting, QR/DataMatrix codes, and more.

- Integrated electrical check (ECOS): to validate electronic functions.

- Modular and flexible: adaptable to various station types (car tunnel, cabinets, assembly desks…)

- Data analysis and Big Data: enables real-time monitoring across the automotive plant.

- Cost-effective and low maintenance solution for quality control in car manufacturing.

Typical MEP station architecture

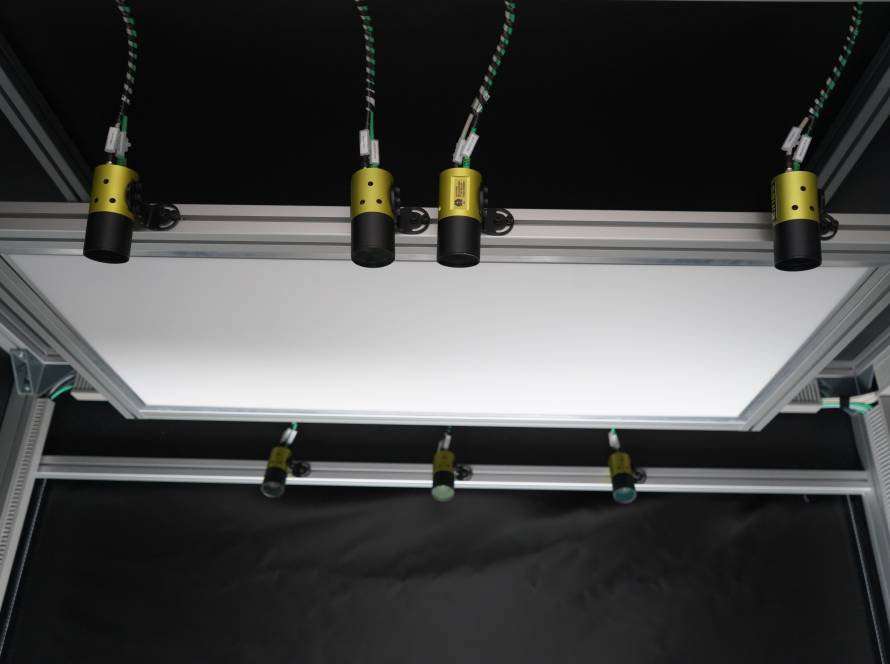

MEP stations typically include:

These stations can also be integrated with robotic guidance systems, AGVs (Automated Guided Vehicles), and 3D process simulations—aligning with the most advanced trends in automation in the automotive industry.

- Mechanical structure

- High-resolution cameras and lighting system

- Intuitive Human-Machine Interface (HMI)

- Ergonomic assembly desk and assembly desk

Error-proofing systems can be integrated at multiple stages —ranging from Tier 1 suppliers, where component quality is verified before shipment (in eMEP cabinets), to OEM final assembly lines (eMEP in Tunnel version), where full-vehicle inspections ensure all parts are correctly positioned and functional. These systems support inspection of both interior and exterior components. If you’d like to learn more about our eMEP tunnel’s capabilities in final assembly—specifically designed for automotive OEMs—you can explore our demo showcasing several component inspection systems.

Want to dive deeper?

If you’re interested in exploring this system in more detail, join our exclusive webinar on July 17th hosted by Salin, where the technical capabilities and benefits of MEP EOL will be presented.

📅 Session 1: 10:00 AM CET

📅 Session 2: 5:00 PM CET

Secure your spot and discover how to transform your auto manufacturing plant into a smart factory powered by automation in car manufacturing and intelligent vision metrology.