As automotive production lines become faster, smarter, and more complex, robot guidance systems are no longer optional—they’re a necessity. At EINES Vision Systems, we’ve developed a solution that addresses this growing need: the EINES 3D Robot Guidance System.

This advanced solution bridges the gap between vision and action, giving robots the intelligence they need to operate with precision, safety, and efficiency in dynamic manufacturing environments.

What is EINES 3D Robot Guidance?

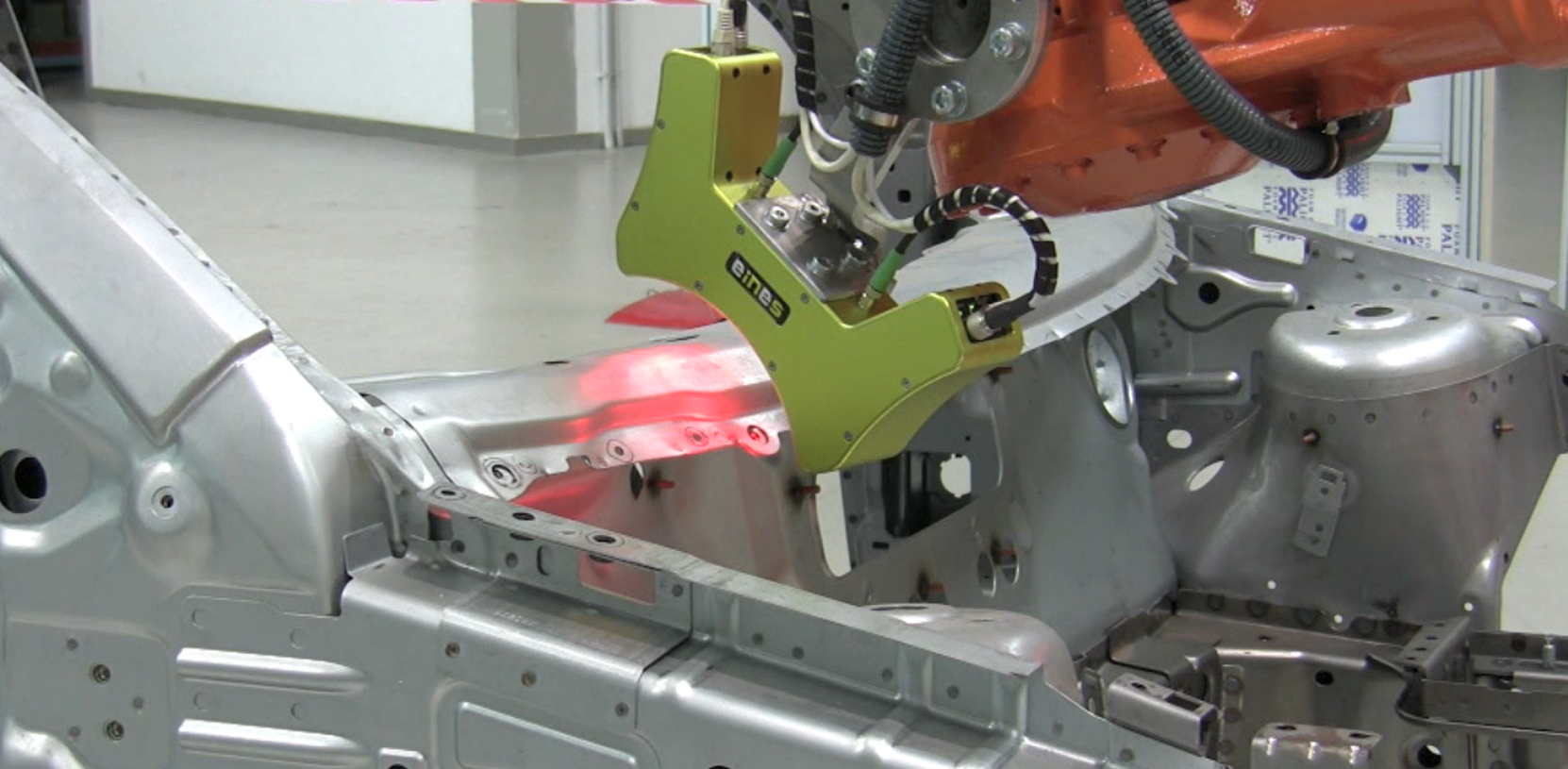

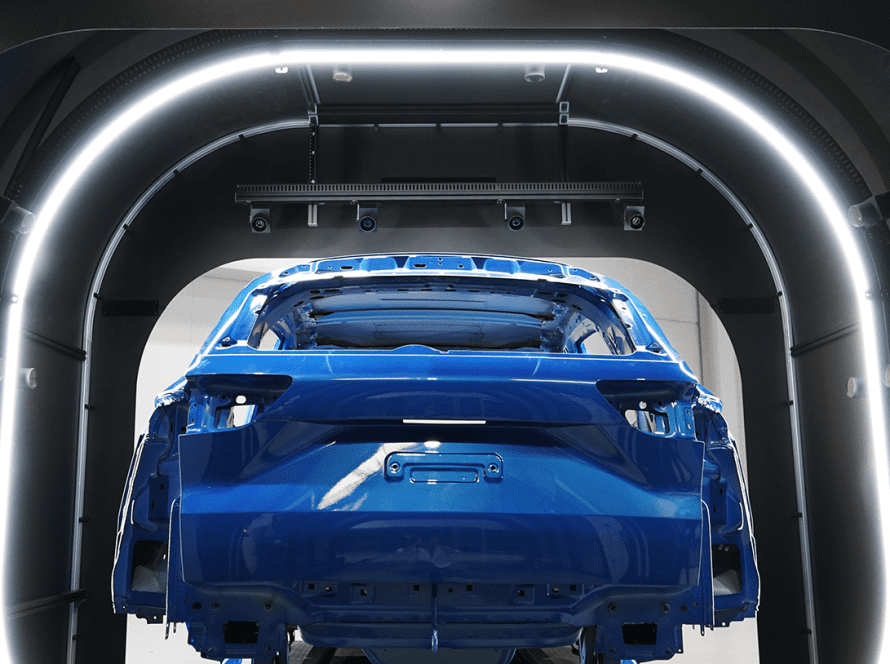

EINES 3D Robot Guidance is a vision-guided robotic system designed to provide real-time positioning and correction data to robots on the production line. It combines 3D stereo vision, laser profiling, and structured light scanning to generate precise information about a vehicle’s structure, gaps, and part positions.

By doing this, robots can adjust their movements dynamically, reducing error margins and ensuring perfect alignment for each task, regardless of small deviations in the vehicle body or part placement.

How Does It Work?

The system uses high-resolution cameras and laser systems mounted either directly on the robot (on-tool configuration) or in fixed positions around the production line. This setup allows the robot to:

- Scan surfaces and features in real time

- Identify exact positions and orientations of parts and panels

- Correct its path dynamically during processes such as adhesive application, part placement, or quality checks

This is particularly useful for tasks like:

- Adhesive bead application guidance

- Patch piece placement

- Tailgate and door assembly guidance

- Gap & flush control

- Glazing assembly

- Steering wheel position before wheel alignment

- Engraving processes

Key Features of EINES 3D Robot Guidance

Real-Time Data Processing

The system operates at production line speed, providing instant corrections without interrupting the cycle time.

Flexible Deployment

It supports gripper-mounted solutions for moving parts or fixed camera setups depending on your plant’s layout and process needs.

Intuitive Software Interface

Operators benefit from user-friendly software, including calibration wizards, visual feedback, and traceability tools, simplifying setup and daily operation.

What are the Benefits?

- Increased Precision: Avoid manual adjustments and reduce defect rates with millimeter-level guidance.

- Cycle Time Optimization: Robots can work at full speed while the system continuously monitors and corrects positioning.

- Enhanced Quality Control: Prevent misalignments and production errors before they happen.

- Adaptability: Compatible with different robotic arms, tools, and manufacturing processes in the automotive industry.

- Simplified Maintenance: The system is built for robustness with low-maintenance components and automated calibration.

Why is this Relevant Now?

The automotive sector is transitioning toward full automation, and the complexity of modern car designs requires solutions that go beyond traditional robot programming. With EINES 3D Robot Guidance, manufacturers can automate gap & flush inspection, adhesive guidance, and part placement, all while maintaining the flexibility to adapt to new models and production changes.

In short, this system supports the shift toward smart factories, where automation, quality control, and real-time decision-making happen simultaneously.

If your plant is looking to combine robotic guidance with precision vision technology, EINES 3D Robot Guidance is ready to help you lead the way.