In today’s fast-paced and highly competitive automotive industry, manufacturers are under constant pressure to innovate, enhance safety, and deliver exceptional performance in their vehicles. This relentless pursuit of cutting-edge technology and improved features often leads to significant investments. However, these investments frequently come at the expense of crucial areas like quality control. As a result, defects at various stages of production can compromise the final product. This article explores the common defects across different production stages and the seven critical errors in automotive quality control that exacerbate these issues.

Stages of Automotive Production and Their Common Defects

1. Press Shop: Metal Parts Fabrication

Common Defects: Dents, deformations, and imperfections in metal sheets.

Statistics: Around 5% of parts produced at this stage may exhibit significant defects. These imperfections can impact the structural integrity and safety of the final vehicle.

2. Body Shop: Vehicle Structure Assembly

Common Defects: Poor welding joints, misalignments, and fitting issues.

Statistics: Defects in the vehicle’s structure can affect up to 3% of vehicles, which is crucial for maintaining structural integrity and safety.

3. Paint Shop: Paint Application

Common Defects: Bubbles, scratches, and uneven paint coverage.

Statistics: Approximately 4% of vehicles might present visible paint defects, affecting both aesthetics and corrosion protection.

4. General Assembly: Major Component Assembly

Common Defects: Loose connections, misaligned parts, and damaged components.

Statistics: Defects in general assembly can impact up to 2% of vehicles, with serious implications for performance and safety.

Source: Assembly Magazine

5. Interior Parts: Installation of Interior Components

5. Interior Parts: Installation of Interior Components

Common Defects: Fit issues, premature wear, and control malfunctions.

Statistics: Defects in interior components can affect up to 6% of vehicles, impacting comfort and user experience.

6. Exterior Parts: Installation of Exterior Components

Common Defects: Misalignments, scratches, and visible damage.

Statistics: Defects in exterior parts can impact around 3% of vehicles, affecting both appearance and aerodynamics.

7. Powertrain Assembly: Engine and Transmission

Common Defects: Oil leaks, synchronization issues, and control system failures.

Statistics: Defects in the powertrain can affect up to 2% of vehicles, with significant effects on performance and efficiency.

8. EV Battery Assembly: Electric Vehicle Batteries

Common Defects: Charging problems, overheating, and energy management failures.

Statistics: Around 1% of assembled EV batteries may present critical defects, affecting vehicle range and safety.

9. Final Assembly: Completing the Vehicle

Common Defects: Assembly errors, incorrect adjustments, and calibration issues.

Statistics: Defects in final assembly can affect up to 2% of vehicles, impacting overall quality and functionality.

The 7 Deadly Sins of Automotive Quality Control

1. Overreliance on Manual Inspection

Issue: Excessive dependence on manual inspections. Consequence: Manual inspection is inherently prone to human error and variability, which can result in missed defects and inconsistent quality.

2. Outdated Inspection Methods

Issue: Continued use of traditional inspection techniques relying on human visual assessment. Consequence: Visual fatigue and subjective assessment can lead to insufficient defect detection and overlooked quality issues.

3. Failure to Implement Advanced Technology

Issue: Lack of integration of artificial vision systems, AI, and advanced lighting technologies. Consequence: The absence of these technologies limits the ability to accurately and swiftly detect defects, impacting overall quality control effectiveness.

4. Inadequate Defect Traceability

Issue: Poor tracking and analysis of recurring defects. Consequence: Without effective traceability, identifying patterns and implementing corrective measures becomes difficult, leading to repeated issues.

5. Lack of Real-Time Data Reporting

Issue: Insufficient real-time data reporting on quality metrics. Consequence: The lack of timely and detailed data hinders informed decision-making and the ability to make immediate process adjustments.

6. Neglecting Preventive Analysis

Issue: Absence of deep learning techniques for preventive analysis. Consequence: Failing to use predictive analytics increases the likelihood of recurring defects and missed opportunities for process improvements.

7. Inadequate Investment in Modernization

Issue: Insufficient investment in modern quality control systems and technologies. Consequence: Not investing in state-of-the-art quality control processes results in less precise inspections and higher costs associated with defects.

Conclusion

Defects in automotive production can arise at any stage, from initial parts manufacturing to final assembly. The reduction in quality control budgets and the failure to invest in advanced technologies are exacerbating these issues.

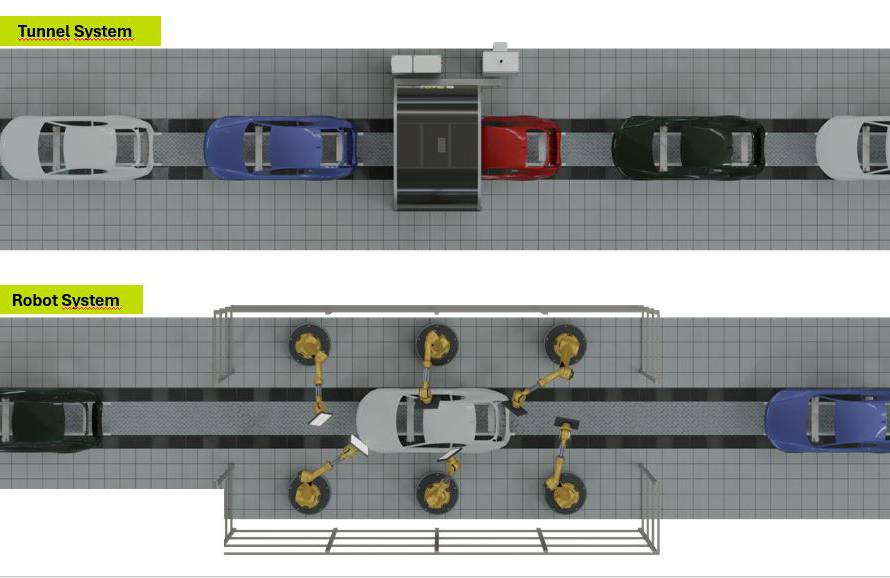

The Solution: EINES VISION SYSTEMS

At EINES Vision Systems, we offer a the most advanced solutions to these challenges. Our quality control systems are powered by vision systems, advanced lighting technologies, artificial intelligence, deep learning, and machine learning. These technologies ensure superior automation, precision, efficiency, and inspection capability throughout any automotive production process.

As pioneers in the development of specialized vision systems for automotive quality control, EINES Vision Systems is committed to enhancing and increasing the accuracy, efficiency, and inspection capacity in automotive production. By integrating our advanced systems, manufacturers can address the seven deadly sins of quality control, ensuring that every vehicle meets the highest standards of quality, safety, and performance, ultimately boosting customer satisfaction and maintaining a competitive edge in the market.

This article is based on the J.D. Power 2022 U.S. Initial Quality Study (IQS), which provides comprehensive insights into defect rates and quality issues across various stages of automotive production. For more details, please refer to the full study available at J.D. Power 2022 U.S. Initial Quality Study (IQS).