In the automotive industry, press shop operations are fast-paced and highly demanding. Every part it produces may carry a defect when a press is damaged or misaligned. This makes early detection critical—because if a defective part isn’t identified in time, it moves forward to body shop and paint, increasing both waste and repair costs.

1. The Limitations of Sampling Inspection: Due to the high-speed nature of press lines, operators often rely on sampling inspection. This means not every part is checked, only a few are manually inspected at intervals. However, this method leaves room for defective parts to go unnoticed. If a press develops a fault, the defect may not be caught until dozens or hundreds of parts have been processed.

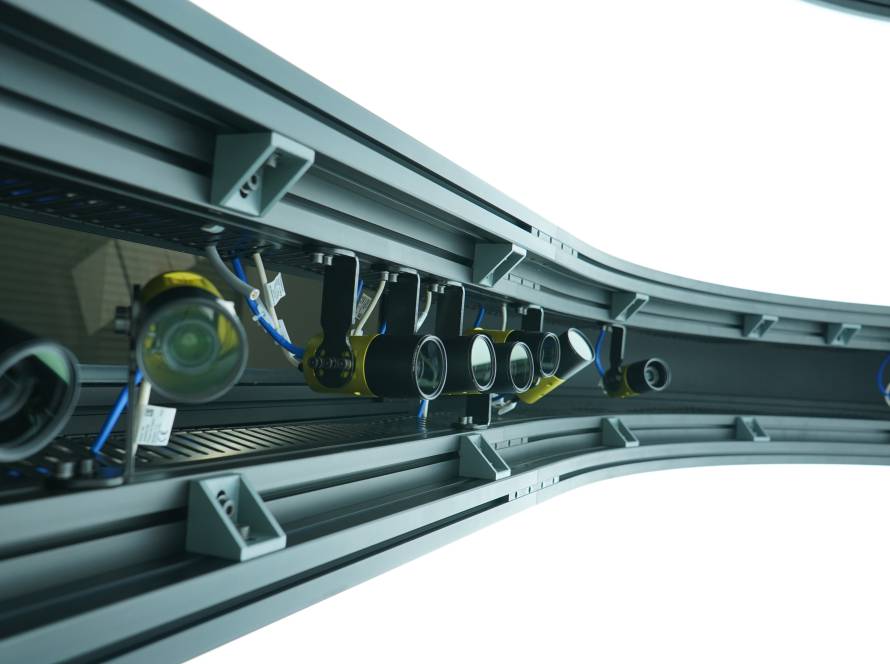

2. Press Lines Are Complex and Costly: Press systems are expensive and highly sensitive to operational errors. A minor alignment issue or wear in the press tooling can result in ongoing defects until the problem is corrected. EINES’ solutions help prevent this by using advanced vision technology to monitor the real-time output. By analyzing part geometry and surface integrity, our systems can identify defects and pinpoint their origin—often before operators even notice there’s an issue.

3. Escalating Costs in Paint and Final Assembly: When a defect is missed during the stamping phase, it’s often only discovered after the part has been welded, assembled, and painted. At this stage, the cost of repair skyrockets. You’re not just reworking a metal panel; you’re stripping paint, reprocessing, and risking production delays. Detecting defects before they leave the press shop is the only way to avoid costly downstream corrections.

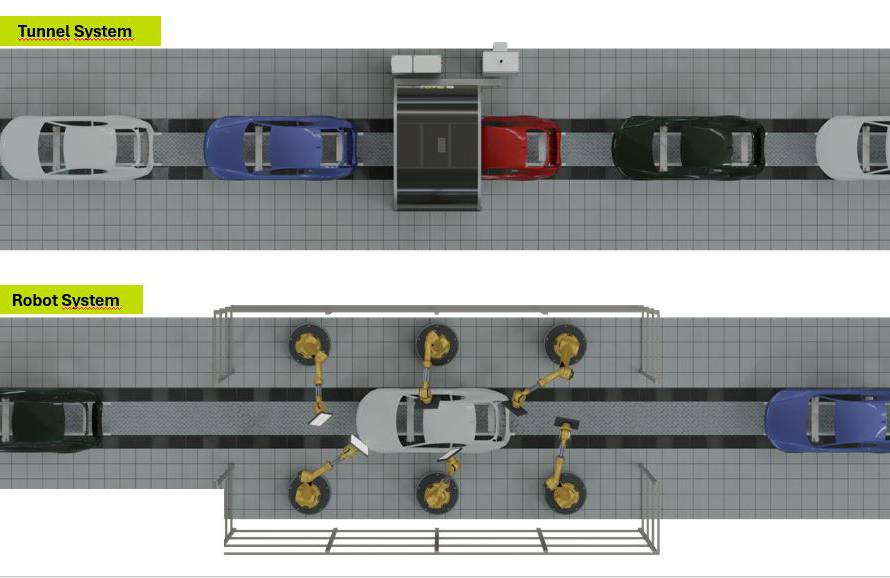

4. 100% Inspection with Vision-Based Systems: Unlike manual methods, our MEP (Multi-error Proofing) for Press Shop solution uses high-speed camera-based inspection to analyse every single part on the line. There’s no guessing, no sampling, no delay. Every panel is scanned for defects, deformations, or critical deviations, allowing real-time feedback and fast root-cause detection. This means you reduce waste, protect downstream processes, and improve overall quality.

Sampling inspection may have worked in the past, but with today’s production speeds and cost pressures, it’s no longer enough. EINES’ vision systems deliver complete, accurate, and scalable inspection for modern press shops— reducing defect manufacturing from the first step of the automotive production line.

Source: ¿Cuáles son los fallos más comunes de las prensas mecánicas?