Vision Systems, Augmented Reality, and Advanced Metrology Solutions

In an era defined by C.A.S.E. (Connected, Autonomous, Shared, Electric) mobility megatrends, the automotive interior has become a cornerstone for user satisfaction and a key differentiator for manufacturers. Beyond aesthetics and innovation, modern interiors must blend technology, comfort, and safety seamlessly. These spaces, now oases of advanced displays, immersive audio, and premium materials, demand innovative designs coupled with uncompromising quality assurance to ensure user delight, comfort, and security on every journey.

To address these evolving challenges, we would like to introduce a transformative suite of technologies for interior inspection and assembly. From advanced artificial vision systems for error-proofing and defect detection to augmented reality solutions that guide operators with precision.

By integrating these innovations, interior manufacturers and OEMs can create interiors that not only meet the highest quality and safety requirements but also redefine the user experience in a sustainable and future-ready way.

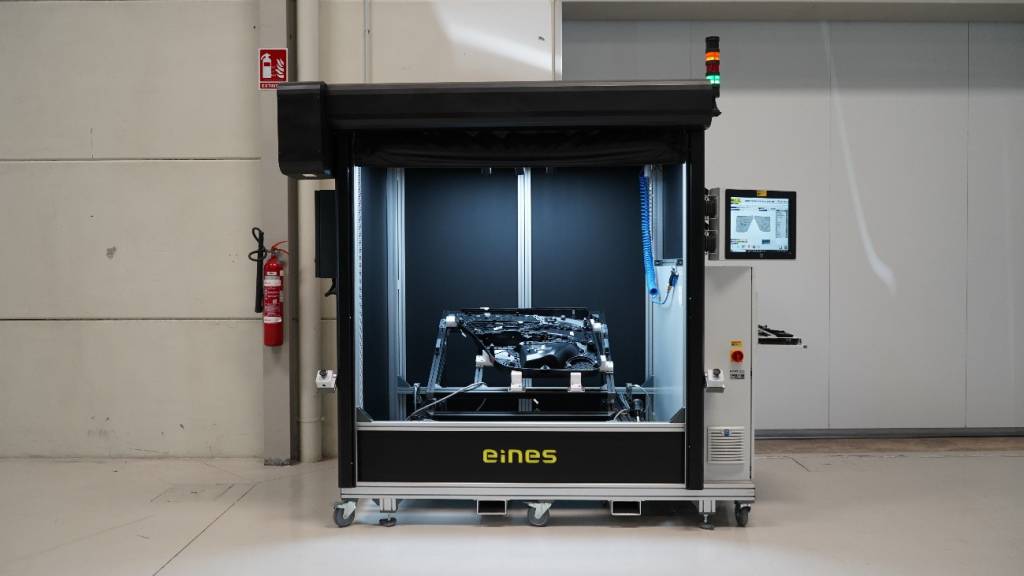

Artificial Vision for Error Proofing

Artificial vision systems play a critical role in error-proofing interior components by leveraging high-resolution cameras, tailored lighting systems, and AI algorithms

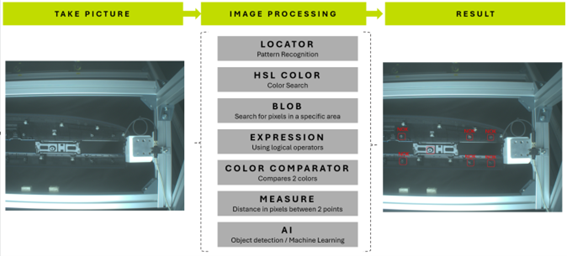

How do these systems work?

The system takes several pictures that are processed depending on the spec it is being checked. After image processing the result is immediately shown on the screens.

These systems ensure:

- Component Presence/Absence and Part-to-Spec Validation: Confirm that every component, from instrumentation panels to door trims, is present and meets precise specifications.

- Surface Defect Detection: Identify contaminations, material transfers, or scratches with unmatched accuracy.

- Electrical Checks: Verify the functional integrity of electrical systems, such as illuminated buttons and display panels.

- Luminous Homogeneity: Evaluate and harmonize lighting systems to deliver consistent color and brightness across displays, backlit buttons, and decorative elements.

Augmented Reality for Operator Guidance

We introduce an augmented reality (AR) solution designed to assist operators during assembly. The system combines:

- Light Projections to indicate the exact placement or alignment of components.

- Visual and Acoustic Alerts to ensure process steps are performed correctly.

- Real-Time Vision Feedback and Object Detection to validate the completion of tasks and eliminate human error.

- This AR-guided process enhances productivity, minimizes rework, and ensures compliance with strict quality standards.

Handheld Laser Profile Technology for Interior Metrology

Measuring gap and flush for interior components is crucial for ensuring the integration of elements such as centre consoles, door panels, and instrument clusters.

Its laser profiling technology offers:

- Rapid and accurate measurements.

- Intuitive operation for ease of use on production lines.

- Enhanced flexibility for inspecting various geometries and materials.

Eines Vision Systems’ portfolio represents a significant leap forward in ensuring quality, safety, and sustainability in automotive interiors. By integrating artificial vision, AR guidance, advanced metrology, and light calibration technologies, we empower manufacturers to meet the evolving expectations of consumers and OEMs in the C.A.S.E. era.

Join us to explore how these innovations redefine the automotive interior experience, combining precision engineering with sustainable practices to create vehicles that are not only functional but truly exceptional.