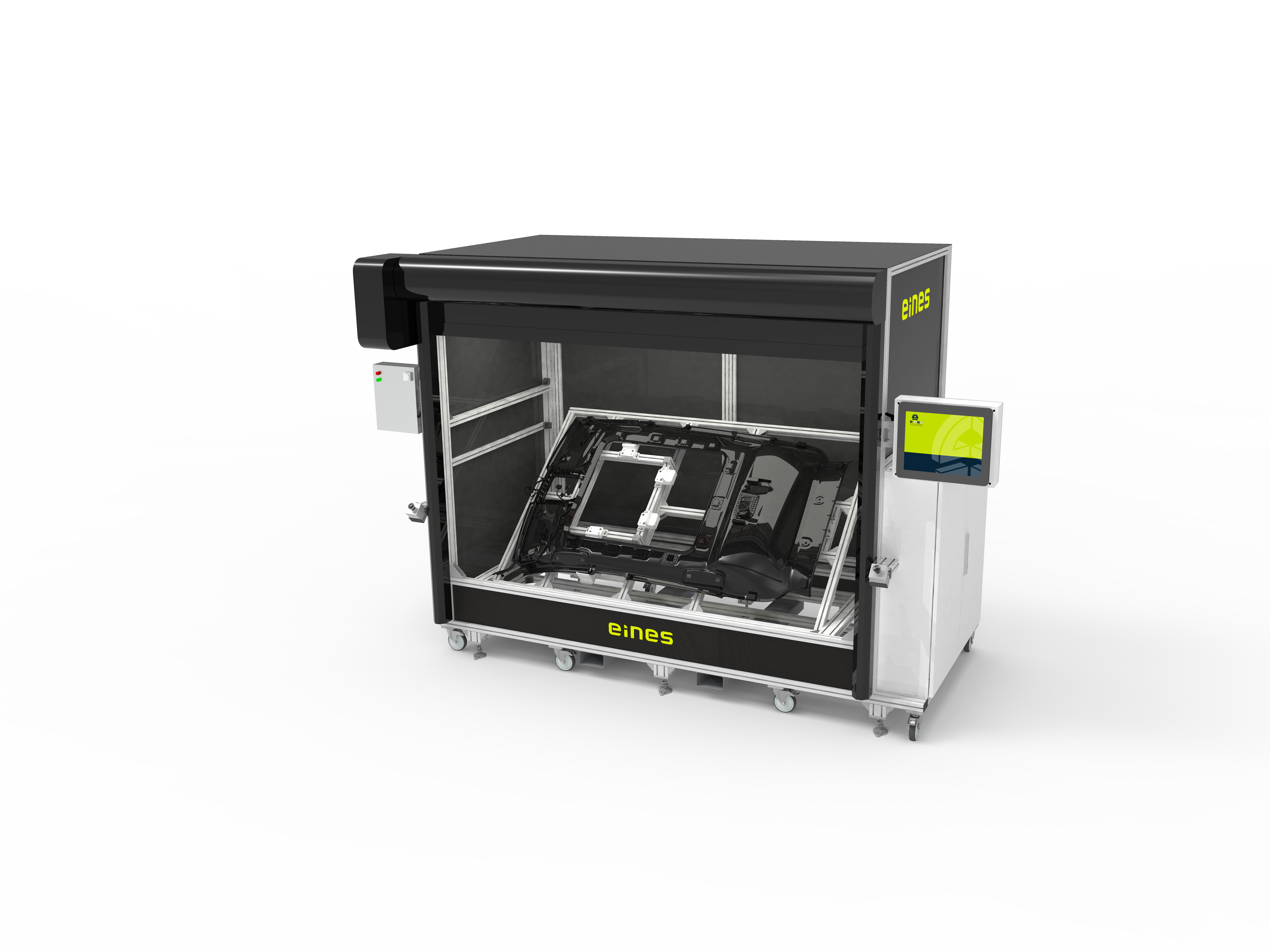

For Parts Check and Error Proofing

Headliners Inspection

End of Line Solution

Headliners Check System is a workbench capable of performing a visual inspection.

It can check several different models without changing tools.

First, the operator is guided in assembly operations, then, the part is visually inspected, and the defects are immediately shown and stored for traceability.

Deep Learning for Component Check

Thanks to Deep learning, the system can detect components with the same colour as the background where they will be located.

Using Artificial Intelligence, taken images are processed differently depending on the external light. This way, images are obtained with constant contrast parameters to ease component detection.

Artificial Intelligence to Improve Performance

Small Footprint

User Friendly and Ergonomic

Traceability and Executable Actions

Flexible and Customizable

Cost Effective and Low Maintenance

Reporting and Big Data

Remote Assistance 24 Hours

We will adapt to your needs at any place in the world thanks to our assistance team.

Our Customer Success Service is focused on promoting a proactive work culture in partnership with our customers. The purpose is to help you as a customer and end user to get more value out of your purchase and stay in close contact with us to share feedback about the installation.