CHALLENGES OF PRODUCTION AND HEADLINER QUALITY CONTROL

Headliners, also known as interior ceilings, represent a critical component in vehicle manufacturing, not only for their aesthetic function but also for their impact on the comfort and performance of the automobile. However, their production and quality control are subject to various challenges that must be addressed to ensure excellence in automotive manufacturing. Below, we will examine the main problems that may arise in the process of production and Headliners Quality Control Inspection:

MATERIAL INSPECTION

Variability in Material Quality: The quality of materials used in headliner manufacturing may vary due to inconsistencies in raw materials, changes in suppliers, or manufacturing process failures. This variability can compromise the durability, appearance, and acoustic performance of the final product.

Material Incompatibility: Incompatibility between materials, such as foam and fabric, can lead to adhesion problems, delamination, or deformation of the headliner. It is crucial to ensure material compatibility to avoid failures in the final product.

Material Contamination: The presence of contaminants during storage, transportation, or processing of materials can affect the quality of the headliner, causing visual defects or performance problems. Strict control measures are necessary to prevent material contamination.

ASSEMBLY AND INSTALLATION

Misalignment and Incorrect Fitting: Misalignment or incorrect fitting of headliner components can result in visible gaps or interference with other vehicle systems, affecting the quality and functionality of the final product.

Damage during Installation: Headliners may suffer damage during the installation process, such as tears or dents, affecting both their appearance and structural integrity. Measures must be implemented to prevent such damage during installation.

Lack of Adhesion between Materials: Lack of adhesion between materials during assembly can lead to delamination or detachment of the headliner, compromising its quality and durability.

Loss of Structural Properties: Some materials may lose their structural properties during assembly, especially under high temperature or pressure conditions, resulting in deformations or loss of support in critical areas of the headliner.

Fit Issues with Other Vehicle Components: Headliners must seamlessly integrate with other vehicle components, and any fit issues may result in visible gaps or interference with the operation of other systems, affecting the perceived quality of the vehicle.

ACOUSTIC INSULATION TESTING

Ineffective Acoustic Insulation: Effective acoustic insulation of the headliner is essential to provide a quiet and comfortable driving experience. Any defects in insulation can result in sound leaks, creating a noisy and uncomfortable environment inside the vehicle.

Sound Leaks due to Installation Deficiencies: Sound leaks may occur if the headliner is not properly installed, allowing exterior noise to penetrate the cabin. Ensuring proper installation is crucial to avoid this issue.

Deterioration of Insulation Material: Over time and exposure to adverse environmental conditions, insulation materials may deteriorate, reducing their effectiveness and requiring periodic replacements to maintain the headliner’s performance.

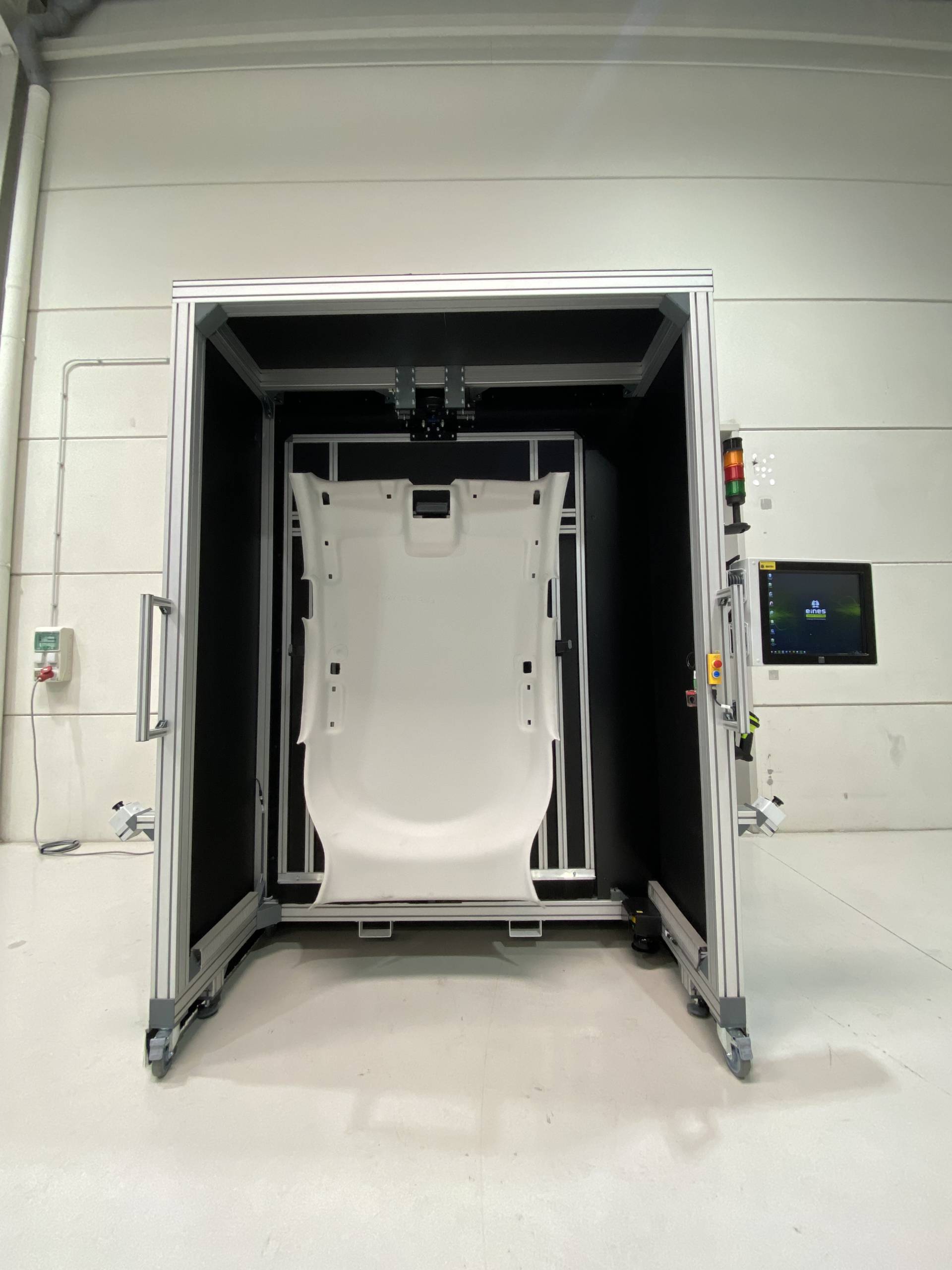

VISUAL INSPECTION

Esthetic Finish Defects: Visual defects, such as wrinkles or stains, can affect the appearance of the headliner and give a perception of low quality. A thorough visual inspection is essential to detect and correct these issues.

Inconsistencies between Production Lots: Significant variations in appearance between different production lots can affect the perceived quality of the vehicle. Ensuring visual consistency is necessary to maintain a uniform experience for all users.

Compliance with Esthetic Design Standards: Headliners must comply with design standards set by the vehicle manufacturer. Any deviations may result in product non-conformity and rejection during quality inspection.

Lack of Texture or Color Uniformity: Lack of uniformity in texture or color of the headliner material may indicate problems during the manufacturing process, affecting the overall aesthetics of the vehicle interior and customer perception of quality.

Exploring Solutions for Automotive Headliner Quality Control Challenges: Join Us!

To sum up, the automotive industry continually encounters challenges in producing and maintaining the quality of headliners. However, effectively tackling these obstacles is indispensable for upholding excellence in automotive manufacturing and ensuring customer satisfaction. As we strive to address these challenges, it’s imperative to seek out the most optimal and efficient solutions, considering the SMART approach.

Lastly, we must ponder: What is the most optimal and efficient solution to address these challenges in a SMART WAY? To explore this question further, we extend a warm invitation to our webinar:

STAY AT THE FOREFRONT IN AUTOMOTIVE INTERIOR PARTS QUALITY CONTROL.

During this webinar, industry leaders will impart cutting-edge strategies and best practices for overcoming production and quality control challenges. Secure your spot now by registering through the link/button provided before.

We eagerly await your participation; seize this invaluable opportunity. Act fast, as slots are limited!*