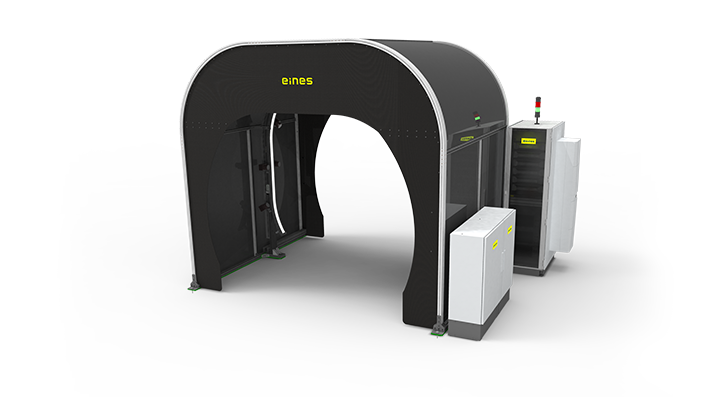

Full Control of the Glass and PU

Our Glazing Solutions have capabilities to control the glass, Primer application and PU application.

It has a guidance insertion with 6 degrees of freedom and 0.2 mm accuracy with non-contact measurement.

Thanks to its flexibility, any model can be measured and as it is our own software, the assistance will be 24 hours.

Customizable Vision System

The possibility of defect detection once the glass is inserted is zero. Our Vision Solution performs different applications:

- Control of the Glass

- Control of the Primer Application

- Control of the PU Application

- Guidance insertion

- Automatic Non-contact measurement

- Marshalling report services

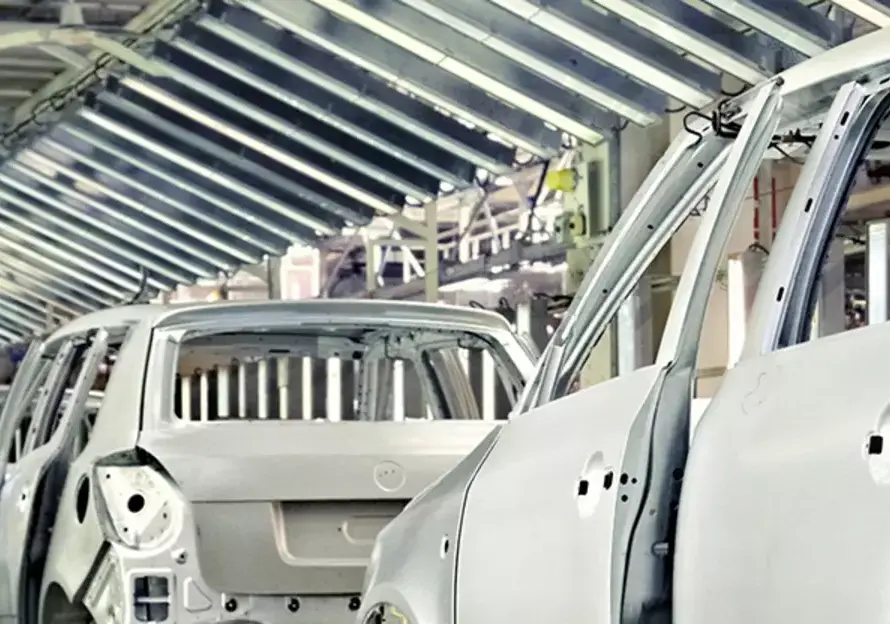

Prevent Water Leaks

Avoid Wind Noise

Sufficient PU Adhesion Strength

Primer Check

Detection in real time of defects

- Primer path position

- Primer width

- Primer gaps

- Overspray (when spraying)

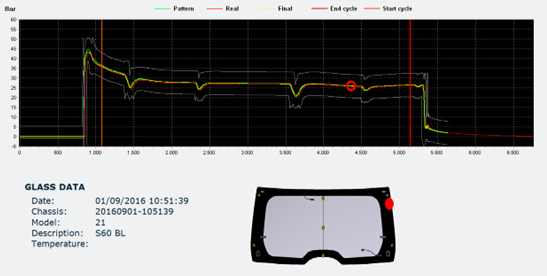

PU Pressure Check

Verifies the pressure of PU application onto the glass parts to prevent water from entering.

Issue Sources

- Discontinuities in the PU bead created by missing material

- Bubbles inside PU material

- Hard particles or lumps

- Problems in the PU dosing system and it´s barrel to the vehicle

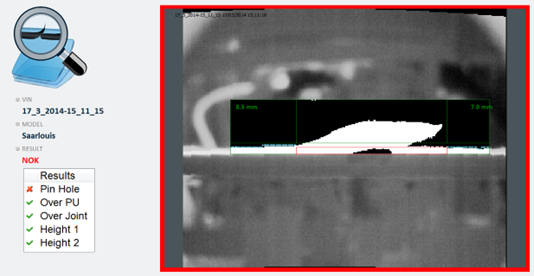

PU Joint Control Check

After the PU Pressure Check has finished finding bubbles and other problems in the PU bead, the PU Joint Control Check uses a thermal camera to look at the most challenging area of the PU bead: where the end of the bead joins the start of the bead.

It will look for too much or too little overlap, as well as the size of the area underneath the overlap, compared with the thickness of the bead above it.

Remote Assistance 24 Hours

We will adapt to your needs at any place in the world thanks to our assistance team.

Our Customer Success Service is focused on promoting a proactive work culture in partnership with our customers. The purpose is to help you as a customer and end user to get more value out of your purchase and stay in close contact with us to share feedback about the installation.