One of the simplest ways to control quality in the automotive sector is through traceability in its processes. Tier 1 suppliers are well aware of this, but how can we truly ensure it? Is there a quick and easy way to generate detailed reports and conduct rapid inspections? At Eines Vision Systems, we know that such tracking allows for quality, safety, and regulatory compliance, ensuring that in the event of a failure, issues can be identified quickly to prevent them from reaching the final product.

Coding system

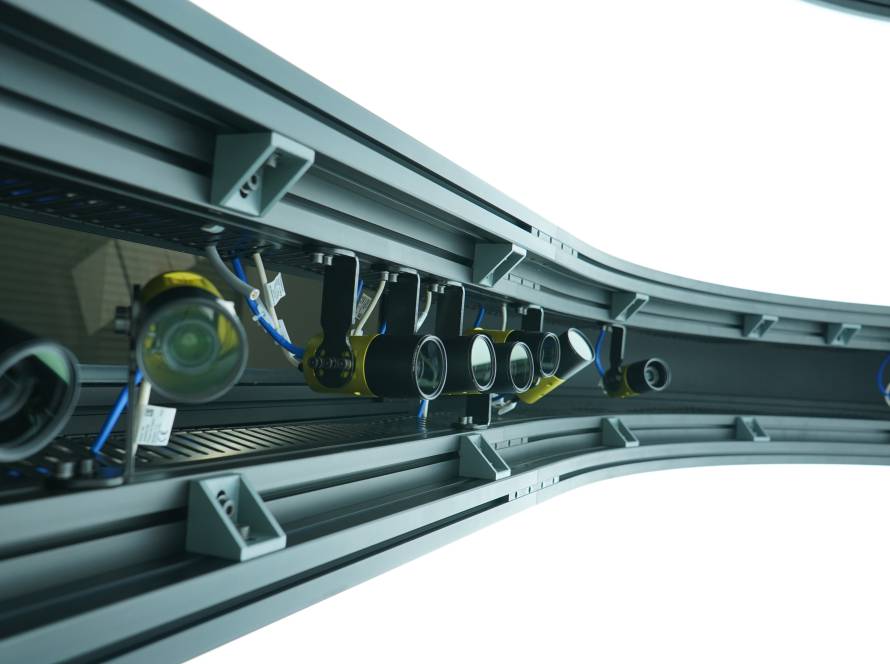

To guarantee traceability, it’s essential to implement a labeling and coding system that assigns a unique code to each part or batch, keeping information accessible at all production stages. And what do we do with this QR code? Once a part has this identifier, our cabins – even though we also have Multi-Error Proofing tunnels – read it to verify through a system if the observed and analyzed part has any faults. Management software like ERP or MES can be critical for storing and managing this information, allowing real-time tracking of each part and preventing manual errors.

More precise and continuos control

Today, more than ever, technologies like Blockchain, IoT, and Machine Learning are optimizing traceability, enabling more precise and continuous control over components. This isn’t only for identifying errors but also for the ability to generate detailed, simple reports of all inspections conducted. This enables us to identify and prevent potential quality issues in a detailed way. Optimization starts with data collection and, of course, analyzing it.

Quality certifications

At Eines Vision Systems, we are committed to robust traceability systems that allow Tier 1 suppliers in the automotive industry to not only ensure quality but also reduce costs and response times in the event of incidents. This also facilitates product recalls, enabling the isolation of affected batches instead of conducting massive and costly recalls. Furthermore, as we know, traceability is a requirement of quality certifications like ISO/TS 16949, which demand full control over every part that reaches the market.