What are Surface Damages?

In automotive manufacturing, Surface Damage refers to any damage that affects the visible surface of the vehicle, especially the bodywork and external components. This type of damage can be classified into two main categories: dents and scratches.

How are They Produced?

Dents

- Impacts During Transportation: During transportation, parts and complete vehicles can suffer impacts due to handling, vibrations, and movement within containers or trucks. Inadequate packaging increases the risk.

- Errors in the Assembly Line: Poorly calibrated automated equipment or human errors can cause impacts on parts during assembly. Additionally, incorrect use of tools can cause dents.

- Improper Handling: Careless handling of parts, whether during storage, movement within the factory, or assembly, can result in dents.

Scratches

- Friction with Objects: Tools, equipment, or components that come into contact with the vehicle’s surface can cause scratches. This includes assembly tools, conveyor belts, and other components of the production line.

- Dust and Particles: In a manufacturing environment, dust and particles in the air can settle on the vehicle’s surface and cause micro-scratches during handling or the painting process.

- Painting Errors: During the painting and drying process, airborne particles can adhere to the wet surface, and accidental contact with other objects or surfaces can cause scratches. Equipment failures can also leave marks.

Impact on the Industry

Surface damage has a significant impact on various aspects of the automotive industry:

- Perception of Quality: Consumers associate vehicle quality with its appearance. Dents and scratches can give the impression that the vehicle is not new or of high quality, affecting customer satisfaction.

- Warranty Costs: Manufacturers often have to cover the costs of repairing these damages under warranty, increasing operational costs.

- Production Delays: Damages detected in the later stages of assembly can cause production delays, as damaged vehicles must be removed for repairs.

Innovations and Future

The automotive industry is adopting advanced technologies to reduce and manage surface damage:

Artificial Intelligence (Machine Learning and Deep Learning)

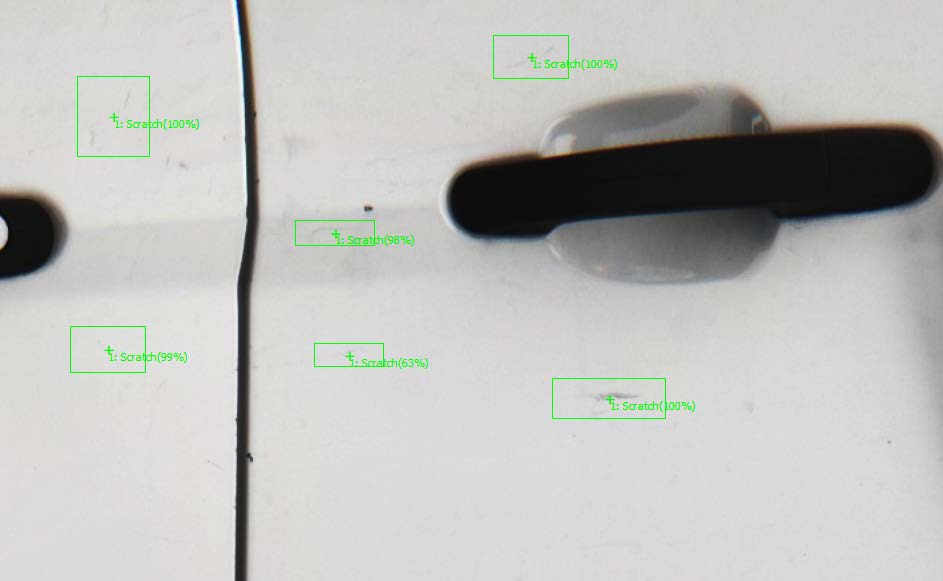

- Damage Detection: AI systems can analyze images and data in real-time to detect dents and scratches. These systems can identify damages that might go unnoticed by the human eye.

- Problem Prediction: Machine learning algorithms can predict where and when damages are most likely to occur, allowing for preventive interventions.

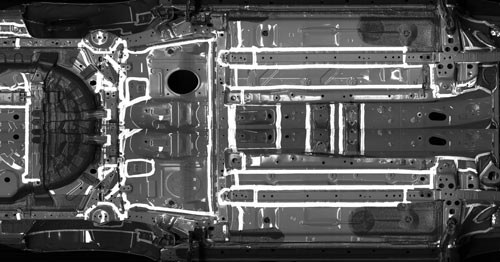

Advanced Automation Through Tunnel Structures

Automated Inspection Tunnels: Equipped with sensors, high-resolution cameras, and AI systems, these tunnels thoroughly inspect vehicles, detecting and recording damages as the vehicle moves through them.

High-Resolution Vision Systems

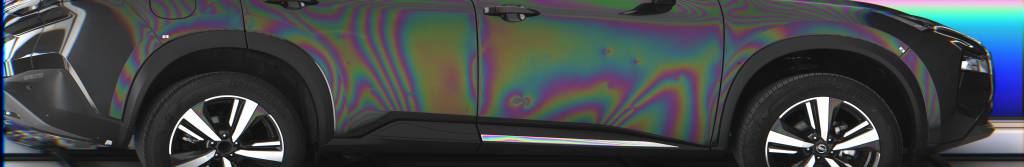

- Cameras and Sensors: High-resolution vision equipment can capture minute details on the vehicle’s surface, allowing for more precise and detailed detection of surface damage.

- Image Analysis: Vision systems use advanced image processing techniques to analyze and evaluate the surface condition in real-time.

InLine Surface Damage Inspector: The Best Solution

In this context of increasing need for precision and efficiency in surface damage detection, Eines Vision Systems introduces the InLine Surface Damage Inspector as the ultimate solution for the automotive industry. Capable of detecting various types of surface defects, such as dents and scratches on the vehicle body, this tool stands out for its use of artificial intelligence and multiple advantages. Our slogan, “Let’s make your plant smarter than ever,” reflects our commitment to innovation and quality.

Features and Advantages

• 100% Inline Inspection: Continuous and complete inspection throughout the manufacturing process, ensuring every vehicle is thoroughly examined without interruptions.

• AI-based Technology: Learns customer specifications and detects claimable errors, eliminating warranty complaints and improving customer satisfaction.

• Non-Touch System without Robots: Minimizes the risk of additional damage during inspection by eliminating the need for physical contact with the vehicle’s surface.

• Flexibility and Small Footprint: Adapts to different production line configurations without requiring much space, allowing easy and quick integration.

• Traceability and Executable Actions: Records each inspection, allowing precise tracking and quick corrective actions to maintain high-quality standards.

• Cost-Effective and Low Maintenance: Reduces operational costs with an efficient and durable solution that requires minimal maintenance.

• Data Analysis and Storage: Offers detailed analysis and data storage to continuously improve the manufacturing process by identifying patterns and trends.

• Reporting and Big Data: Generates detailed reports and uses big data to optimize quality and production efficiency.

Technical Concept

The unique Zebra Arch allows the system to detect light distortions. The cameras capture thousands of images and compare them with each other, enabling the artificial intelligence algorithm to identify distortions and find surface defects with unprecedented precision.

Human Machine Interface

The vision system provides immediate feedback through a user-friendly interface. The intuitive interface allows operators to see any detected defects in real-time and make informed decisions quickly. Additionally, it features integrated reporting, essential for analyzing performance and making adjustments in the manufacturing process.

Quality Control

Quality control is essential to ensure that vehicles do not have surface damage when they leave the production line. Best practices include:

• Automated Tunnels: Equipped with vision systems and artificial intelligence, these tunnels allow detailed and precise inspection of each vehicle. They can detect even the smallest damages that might go unnoticed in a manual inspection.

• Vision Systems and Artificial Intelligence: These systems combine high-resolution cameras with advanced AI algorithms to analyze vehicle surfaces in real-time, detecting any discrepancies.

Conclusion

With our InLine Surface Damage Inspector, the automotive industry has an advanced and effective tool for detecting surface damage. Integrating artificial intelligence, high-resolution vision systems, and innovative technology, this solution ensures that vehicles maintain the highest possible quality, reducing operational costs and increasing customer satisfaction. This comprehensive approach to detecting and managing dents and scratches redefines the quality standard in automotive manufacturing. With Eines Vision Systems, “Let’s make your plant smarter than ever.”