Introduction

n previous articles, we discussed classification, object detection, and segmentation, three fundamental techniques that help machines “see” and understand image content. However, there are cases where defects or errors cannot be anticipated, either because there are not enough prior examples or because the variability of the defects is so high that simulating every possible scenario is impossible. This is where anomaly detection takes center stage.

Anomaly Detection

Anomaly detection focuses on identifying elements or patterns that do not fit within what is considered “normal” in a dataset. Unlike the previously mentioned techniques, which often rely on labeled examples of defects, anomaly detection is based on learning what is correct. The system learns to recognize the ideal state of a part or process and detects any significant deviation.

Inspection of Automotive Parts

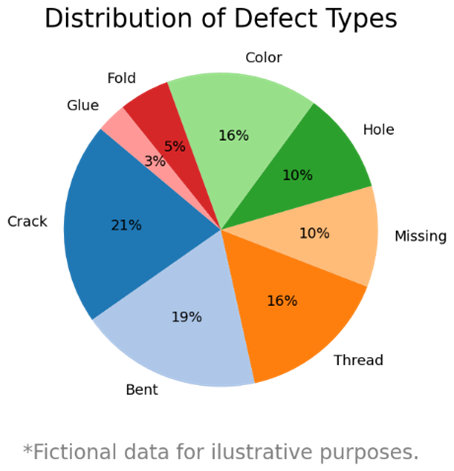

For example, in the inspection of automotive parts, anomaly detection can be applied to surfaces such as textiles, stitches, plastics, or wooden finishes. It can also address more general defects, such as parts that are out of place, missing materials, or foreign objects on the production line. This is particularly useful in production environments where defect variability or anomalies are high and unpredictable.

Anomaly Detection are trained?

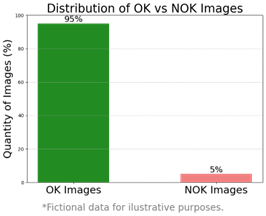

Anomaly detection models are primarily trained using images of correct parts. This approach enables the model to identify normal patterns and construct a precise representation of what is expected. When a part or process deviates from this pattern, the system marks it as an anomaly.

These architectures allow the model to reconstruct images of correct parts and compare the result with the original image. In addition to identifying whether an image is anomalous, the system can precisely indicate the exact area where the anomaly is located. For instance, it can detect defects in the pins of a connector or identify imperfections in complex surfaces such as leather, textiles, or glass with previously unseen morphologies, clearly marking the affected areas. Significant differences between the reconstructed and original images reveal defects that might go unnoticed with other methods.

Conclusion

To conclude, anomaly detection complements the other computer vision techniques in scenarios where defects are unexpected or infrequent. In our systems, we use state-of-the-art models that combine speed and precision to ensure quality at every stage of production, along with custom tools for training and inspection tailored to our clients’ needs.

With this, we conclude our series of articles on the main computer vision techniques based on deep leaning for industry. Choosing the right technology depends on the specific use case, and our experts at Eines are here to help you find the ideal solution for each challenge.

If you have questions or need more information, feel free to contact us at www.eines.com.