Welding problems and their impact

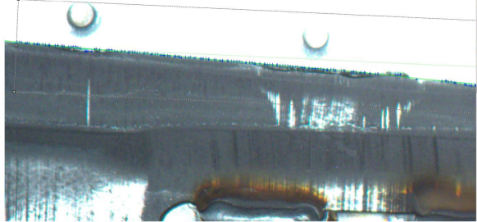

In modern vehicle production, weld seams are structural elements. They guarantee safety, durability, and performance. However, even the smallest welding defect can have consequences:

- Structural risk: cracks, pores, or misaligned seams may weaken the body structure.

- Increased costs: defects discovered late in production often mean expensive reworks or, in the worst cases, scrapping entire parts.

- Customer dissatisfaction: vehicles with inconsistent welds can lead to warranty claims and reputational damage.

Traditional inspection methods, mainly manual visual checks, are not only slow but also subject to human error. In high-volume production, this lack of precision can allow defective welds to pass unnoticed.

How to avoid it?

The solution lies in automatic weld inspection with machine vision. By integrating industrial cameras, controlled lighting, and advanced software, the process becomes both faster and more reliable.

Instead of sampling a small percentage of welds or relying on visual inspection, every single weld seam can be analyzed in real time. This ensures that defective welds are detected immediately, before the body moves forward in the production line, reducing waste and improving quality assurance.

How does this technique work?

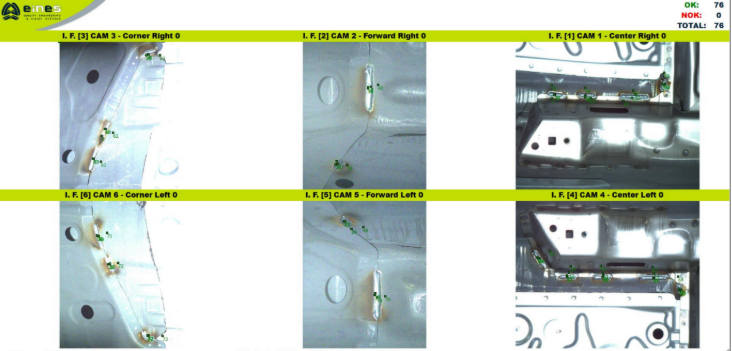

The technology behind automatic weld inspection is eMEP (Eines Multi Error-Proofing System), developed by EINES Systems.

At its core, eMEP combines:

- Industrial vision cameras: capture detailed images of weld seams under controlled conditions.

- Specialized lighting: eliminates shadows and reflections to ensure image consistency.

- Advanced image processing algorithms: detect, measure, and evaluate weld characteristics with high precision.

By integrating these components, the system provides real-time inspection, automatic feedback, and full traceability. Operators don’t just see whether a weld is correct or not — they also get a digital report with images, data, and results for every seam inspected.

Image processing techniques (powered by eMEP) applied to Welding Check

One of the key strengths of eMEP is the wide set of image-processing tools it offers, which can be tailored to the needs of weld inspection:

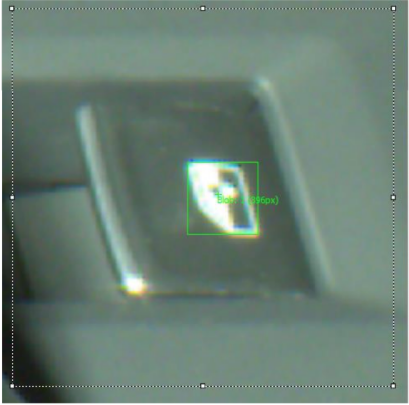

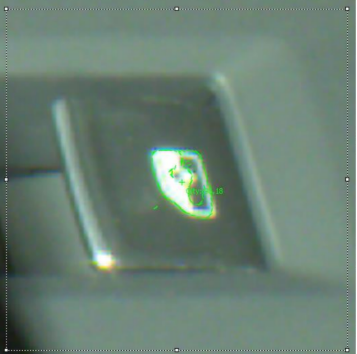

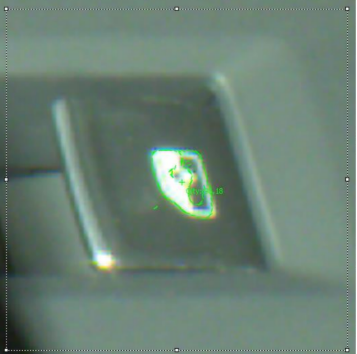

- BLOB: detects clusters of black or white pixels, ideal for spotting pores, holes, or surface burn marks.

- Locator: identifies a precise pattern, used to locate the exact weld seam area before inspection.

- Bead: verifies the size and continuity of a weld seam, ensuring the bead matches expected dimensions.

- Trend: analyzes the direction of a line to evaluate whether the weld follows the correct path.

- Edge Inspect : measures between edges of a part, confirming the weld is placed in the designated zone.

- Object Detection: uses machine learning to identify complex weld defects, adapting to variations that are hard to capture with simple rules.

- Multiple Object Detection:detects several defects simultaneously, which is especially useful in long weld seams.

- Measure: provides accurate measurements of distances and sizes, such as weld bead width and height, in millimeters or pixels.

Benefits of applying eMEP to Welding Check

The implementation of eMEP in welding inspection delivers multiple advantages:

- Precision and reliability: inspections are done with micrometric accuracy, eliminating the subjectivity of manual checks.

- Real-time feedback: any detected defect is flagged immediately, allowing corrective actions on the spot.

- Cost efficiency: by reducing rework, scrap, and warranty claims, the system delivers measurable savings.

- Complete traceability: every weld is documented with images, data, and results, creating a digital archive of the entire process.

- Process optimization: beyond detecting defects, data collected by eMEP allows trend analysis and continuous improvement.

- Operator support: instead of spending time on repetitive visual checks, staff can focus on solving problems and optimizing production.

Beyond welding: the versatility of eMEP

Although Welding Check is one of the most impactful applications, eMEP is not limited to weld inspection. Its modular approach means it can be adapted to other critical areas of assembly, such as adhesive bead verification, component placement, or dimensional checks.

This flexibility makes eMEP a long-term solution for error-proofing across the entire production line, not just welding.

Want to know more?

Welding Check with eMEP demonstrates how machine vision and advanced error-proofing can elevate quality assurance to the next level. By combining industrial hardware, smart software, and powerful image processing, manufacturers can achieve consistent weld quality, reduce costs, and build safer, more reliable vehicles.

If you want to learn more about how eMEP can transform your welding inspections or other error-proofing processes, get in touch with us — quality has never been this precise.