DOT Problems and Their Impact

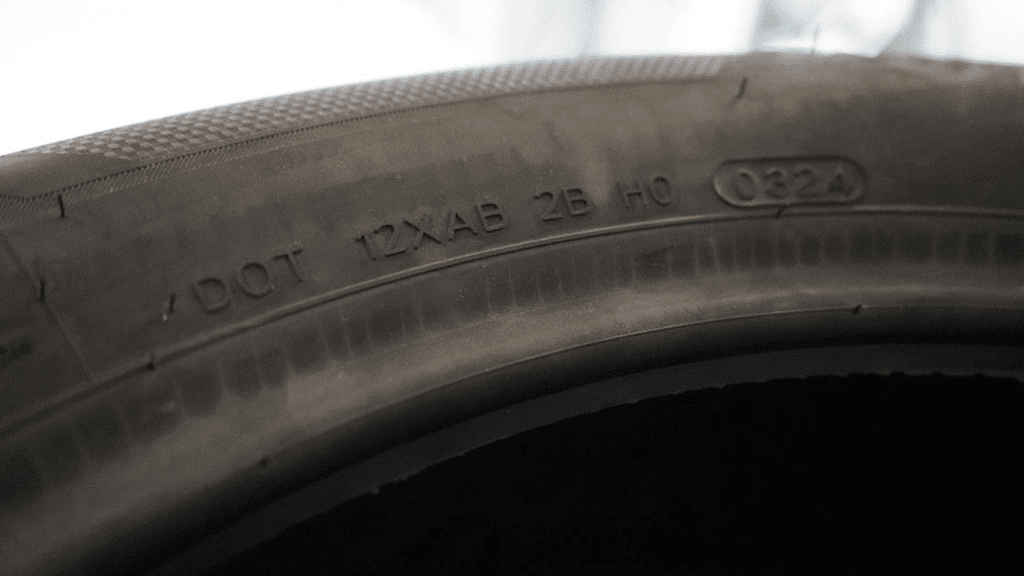

In tire manufacturing, traceability and compliance are essential for both safety and quality assurance. Every tire must display a Department of Transportation (DOT) code, which contains critical information such as manufacturer, plant location, and production date. This code acts as the tire’s unique identity, required for audits, recalls, and warranty management.

Traditionally, DOT codes have been read and verified manually. However, this approach comes with challenges:

- Human errors in transcription or interpretation.

- Slowdowns in production lines when codes are difficult to read.

- Inconsistent results, depending on operator fatigue or conditions.

- Regulatory risks, including non-compliance or difficulties during recalls.

Such limitations can lead to costly warranty claims and even damage a manufacturer’s reputation.

How to Avoid It? Automated DOT Code Verification with Machine Vision

To overcome these issues, manufacturers are adopting automated vision systems that guarantee precision and speed.

AutoDOT is designed to fully automate the reading and verification of DOT codes. Using advanced cameras and OCR (Optical Character Recognition) powered by AI, AutoDOT inspects tires in real time—delivering unmatched consistency and accuracy. It ensures that no tire leaves the production line without a verified and traceable identity.

How Does AutoDOT Work?

AutoDOT integrates cameras, lighting, and intelligent algorithms into a compact inspection system that runs directly in the production line.

Here’s how it works step by step:

- Tire Detection: Sensors identify when a tire enters the inspection point.

- Image Capture: High-resolution cameras take multiple images of the DOT code from different angles.

- OCR Processing: Optical Character Recognition algorithms instantly read and interpret the code.

- Verification: The system confirms that the code is complete, accurate, and compliant.

- Data Logging: Each code is stored digitally, creating a full traceability record for audits, recalls, and quality checks.

The entire process happens at production speed, with no interruptions—ensuring high throughput while maintaining quality standards.

Image Processing Techniques in AutoDOT

AutoDOT employs state-of-the-art vision techniques to ensure reliability, including:

- AI-driven OCR: Reads DOT codes even in challenging conditions (e.g., low contrast, curved surfaces).

- Multi-angle Coverage: Prevents blind spots by capturing images from three perspectives.

- Adaptive Lighting: LED lighting minimizes glare and enhances image clarity.

- Real-Time Alerts: Any unreadable or incomplete code triggers instant alerts or rejection signals.

This ensures that every tire is correctly identified, while maintaining high efficiency in the production line.

Benefits of AutoDOT

The adoption of AutoDOT delivers significant advantages for tire manufacturers:

- Complete Traceability: Each tire’s DOT code is stored and accessible for future verification.

- High Speed: Operates at high speed without slowing down the production line.

- Error Elimination: Removes the risk of mistakes common in manual inspection.

- Compliance Assurance: Ensures regulatory standards are met consistently.

- Low Maintenance: Designed with no moving parts, minimizing upkeep and downtime.

- Future-Proof: AI algorithms continue to improve accuracy over time.

- Operational Efficiency: By avoiding rework, recalls, and bottlenecks, AutoDOT reduces costs and boosts productivity.

Want to Know More?

AutoDOT is transforming tire inspection and traceability. By combining automated vision and OCR technology, it enables manufacturers to reduce risks, cut costs, and achieve higher efficiency.

In a competitive automotive industry where precision is non-negotiable, AutoDOT delivers the confidence and compliance that modern manufacturers demand.

Interested in learning more about how AutoDOT can optimize your production line? Contact us today and let’s start the conversation.