Wheel and Tire Inspector: Innovation in Tire Visual Inspection

An advanced Wheel & Tire Visual inspection is a crucial process in manufacturing, ensuring that each product meets the highest standards of quality and safety. In this context, Eines Vision Systems has developed a revolutionary solution: the Wheel and Tire Inspector – Automatic DOT Code Reader. This automated system not only enhances the precision and efficiency of visual inspection but also significantly simplifies the process of reading DOT and DOM codes on tires.

Technological Innovation in Visual Inspection

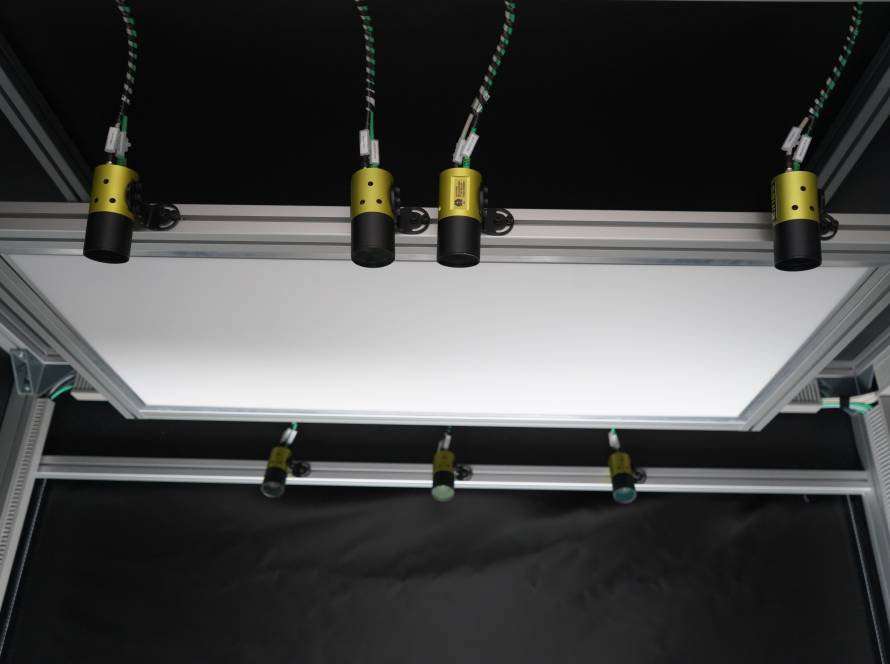

Use of Cameras and Lasers

Our system uses an advanced combination of cameras and lasers to scan the tire and obtain a detailed three-dimensional model. The model allows sophisticated software algorithms to read and analyze all the inscriptions and symbols imprinted on the tire automatically. This technology ensures that each inspected tire meets the most rigorous quality standards, eliminating human errors and improving inspection consistency.

Implementation Options

We offer this solution both as an automated machine and as a handheld device, providing flexibility for manufacturers to choose the option that best suits their operational needs and available plant space.

System Features

Gentle Handling and Maximum Precision

The system uses a belt conveyor to move the tires through the inspection process without the need for manual centering. A gentle handling minimizes the physical impact on the tires while ensuring precise and efficient testing. The system’s design focuses on maintaining tire integrity while maximizing inspection accuracy.

Automatic Reading of DOT and DOM Codes

Our TIRE DOT Reader provides a comprehensive solution for capturing DOT and DOM codes, eliminating the need for multiple specialized testing stations. This integrated approach reduces inspection times and enhances the overall efficiency of the manufacturing process.

Benefits of the Wheel and Tire Inspector

• High Speed and Precision

• High Data Rate and Perfect Synchronization

• Reduction of Specialized Testing Stations

Importance of Visual Inspection in Tire Manufacturing

Visual inspection is fundamental for preventing defects, ensuring safety, and maintaining quality. With the Wheel and Tire Inspector, these inspections are carried out more accurately and efficiently, ensuring that each tire reaching the market meets the industry’s highest standards.

Conclusion

The Wheel and Tire Inspector – Automatic DOT Code Reader from Eines Vision Systems represents a significant advancement in tire visual inspection. With its combination of cameras and lasers, flexible implementation options, and capability to automatically read DOT and DOM codes, this system offers a comprehensive solution that enhances precision, efficiency, and safety in tire manufacturing. By integrating this technology, manufacturers can optimize their production processes, reduce operational costs, and ensure that each tire meets the highest standards of quality and safety.