Parts Inspection

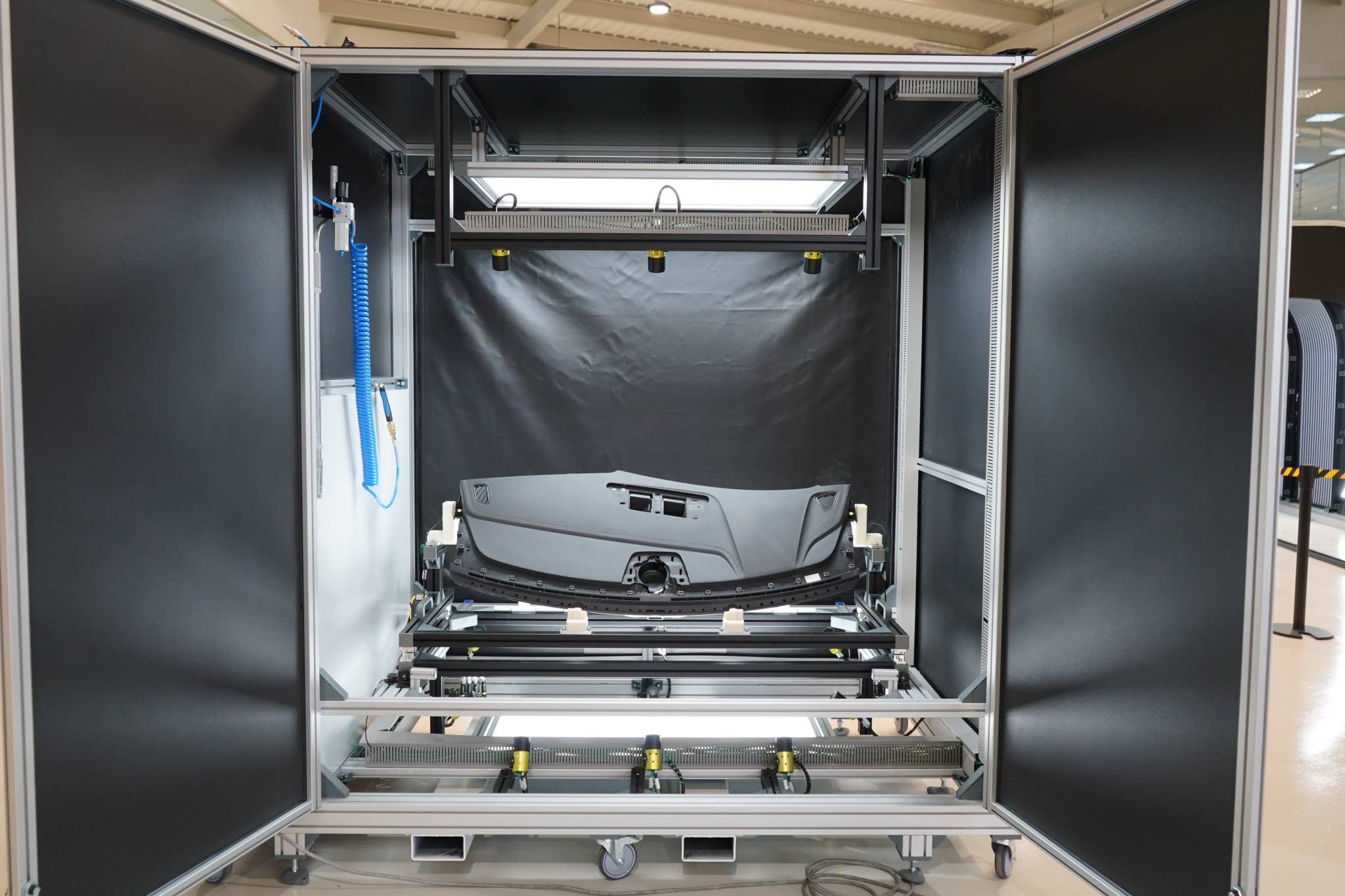

Stamping Part Inspection System

Inline Error-Proofing for Stamped Parts in Press Shop

The Press Shop eMEP system is a compact, inline error-proofing tunnel designed for the inspection of freshly stamped metal parts. Using specular light and high-resolution cameras, it compares each part against a “master” to detect stamping defects such as missing holes, burrs, cracks, or deformations. Ideal for press shop quality control, this system ensures zero-defect stamping in automotive production

eMEP Cabinets for Interior and Trim Inspection

Part-to-spec verification, code reading, lighting and surface control in one smart station

Eines Multi-Error Proofing End-of-Line (eMEP EOL) Cabinets are versatile stations for semi-automated inspection of complex interior parts, including doors, cockpits, roofs, lighting panels, and instrument clusters. They combine vision-based part-to-spec checks with code reading, positioning control, adhesive contamination detection, lighting validation, and even electrical check-out. Designed for flexibility and reliability in final assembly quality control.

Ergonomic handheld system for fast, offline or final-stage validation

The eh2 is a handheld device that accurately measures gap and flush using advanced laser and camera technology. Lightweight and ergonomic, it provides instant and reliable readings with an intuitive user interface. Ideal for offline metrology checks, final inspections, and quick quality validation in car body assembly, this tool supports robust quality control without interrupting the line.

Sealer Bead Inspection for Leak-Free Assemblies

The Sealer Check system uses strategically placed cameras to inspect adhesive and sealing bead application along the vehicle body. It measures bead thickness, continuity, position, and overall quality to ensure perfect sealing. This sealer inspection solution is critical for achieving watertight and airtight vehicle assemblies and preventing long-term reliability issues.

Welding Check

Weld Quality Inspection for Safe and Strong Assemblies

The Welding Check system uses high-resolution cameras to inspect the quality and position of weld beads directly on the line. It ensures structural integrity by verifying weld continuity, presence, alignment, and proper fusion. This solution is key for guaranteeing robust joining and avoiding rework or safety issues in the final vehicle structure.

Pressure Monitoring for Glazing Sealant Application

The Pressure Check system is part of EINES’ glazing solutions and monitors the pressure applied during sealant dispensing for windows and windshields. Using sensors and advanced software, it detects pressure variations that indicate problems like air bubbles, particles, or application inconsistencies. This inline glazing inspection ensures optimal bonding, sealing performance, and long-term durability.

You can also search your solution through the different Automotive stages