Say gooodbye to Paint Defects

Achieve Zero Paint Defects Car Bodies

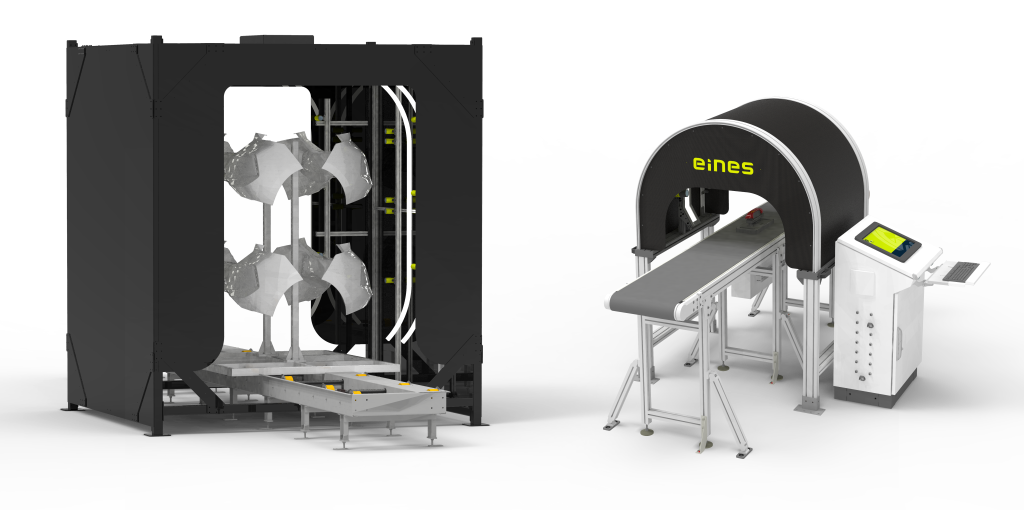

Revolutionary precision in paint defect detection brings new standards to surface inspection. The Eines Surface Quality Paint Inspector automatically detects, locates, and classifies even the tiniest paint defects in real time — with no line stops.

Powered by high-sensitivity machine vision technology and AI, it ensures flawless car bodies straight from the line.

Pushing the limits of automated quality control: no manual inspection, no rework delays — and full compatibility with automatic sanding and polishing systems.

Technology | Powered by us

The tunnel uses high-resolution cameras and a white arc LED lighting system to analyze how light reflects across the vehicle’s surface. Any distortion in this reflection reveals paint imperfections that would otherwise go unnoticed.

With the system you can achieve:

– Severity-based defect classification

– 3D mapping of each defect

– Data ready for robotic repair

– Fully compatible with moving production lines

This advanced combination of optics and AI ensures a highly accurate inspection process, consistently high-quality finishes, and seamless integration into fast-paced production line.

Digitalization

This connected ecosystem of data empowers manufacturers to compare performance across multiple plants, using cross-plant analyses to uncover systemic issues or material inconsistencies.

This solution transforms quality control into a predictive, data-driven process that helps OEMs and tier1 improve efficiency, reduce costs, and consistently deliver top-quality vehicles.

News that might interest you...

*It depends on your particular case

Technology applicable to part paint inspection

The same advanced technology used for full-carbody inspection is also adaptable to smaller parts, such as bumpers, mirrors, handles, or individual body panels.

With tailored configurations, the system maintains the same level of precision in defect detection, ensuring consistent quality control across all stages of production, regardless of the part size.

What stands out this solution?

of the process to the customer’s specific plant layout, production flow, and quality standards.

.of handling various defect types, vehicle models, and production phases with minimal reconfiguration.

enabling easy maintenance, quick part replacement, and scalable system upgrades without production downtime.